— November 26, 2025

At the heart of modern heavy equipment is a complex system of fluids. For heavy equipment to function properly, fuel, oil, coolant, hydraulic fluid and other liquids need to be moved around at precise rates and at exact moments.

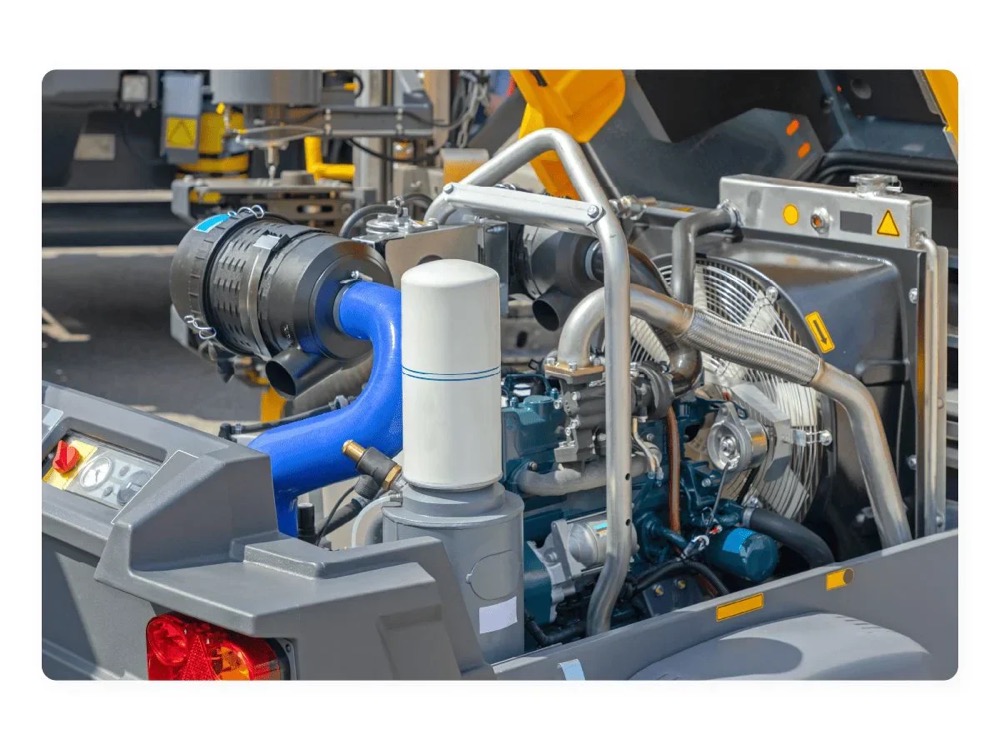

Central to this process is a vast network of sealed hoses and fittings designed to move fluid between a machine’s components smoothly and efficiently. Modern heavy equipment features dozens of different types of hoses and fittings, each designed for a specific fluid and purpose.

A machine’s hydraulic system, for example, transports hydraulic fluid via hydraulic hoses, whereas radiator hoses connect the radiator to the engine, allowing for coolant to circulate between the two components.

Given the sheer number of hoses at work in heavy equipment, it can be challenging to understand the role of each hose and how it should be maintained. In this guide, we’ll go over the main types of hoses you’re likely to encounter on your heavy equipment. By understanding the role of each type of hose in your machine, you can properly care for these key components, thereby improving your machine’s performance and longevity.

While the number and types of hoses found in your machine will depend on the machine’s exact make and model, certain hoses are nearly universal and can be found in most heavy equipment.

Here are the most common types of hoses you’re likely to encounter in heavy construction equipment, along with their function and specific maintenance requirements.

Fuel hoses are responsible for transporting fuel from the fuel tank to the engine, ensuring a steady supply of fuel for combustion.

These hoses are typically made from reinforced rubber or synthetic compounds designed to withstand the corrosive nature of fuel and high-pressure conditions.

The cost to replace fuel hoses on heavy equipment can vary depending on the size and type of equipment, but it is generally in the range of $20 to $50 per hose, not including installation.

Fuel hoses on heavy equipment should be inspected regularly and replaced every 3 to 5 years or as needed, depending on wear, tear and exposure to harsh conditions.

Fuel hoses are usually found running from the fuel tank to the engine, passing through the chassis and engine compartment.

Signs it needs replacing:

Cracks, leaks, bulges or soft spots in the fuel hose are signs it needs to be replaced. Additionally, decreased fuel efficiency, loss of power, rough idling or difficulty starting the equipment may indicate a problem with the fuel delivery system.

Hydraulic hoses transmit pressurized hydraulic fluid to various components, such as between the hydraulic fluid reservoir and hydraulic cylinders along an excavator’s boom arm.

These hoses are critical to the function of modern heavy equipment, as they enable crucial functions like lifting and digging; they also provide power to attachments. Hydraulic hoses have uses in other critical systems as well, such as in a machine’s braking system.

Hydraulic hoses are typically constructed with layers of high-strength synthetic materials, such as reinforced rubber or thermoplastic, to handle the high pressure and flexibility requirements of hydraulic systems.

The cost to replace hydraulic hoses can vary significantly based on the size, length and type of equipment. Costs can range from $50 to $500 or more per hose, not including installation.

Regular inspection is essential, and hydraulic hoses should be replaced every 3 to 5 years or as needed, depending on wear and tear. A hydraulic hose that has sprung a leak can be potentially lethal to operators, and should be handled with extreme care.

Hydraulic hoses are routed throughout the heavy equipment, connecting the hydraulic pump to cylinders, valves and other hydraulic components.

Common signs of hydraulic hose issues include leaks, visible damage or cracks, reduced performance or response from hydraulic systems, loss of power and a drop in hydraulic fluid levels.

Coolant hoses, which include both upper and lower radiator hoses, are part of the cooling system and ensure the proper temperature regulation of the engine.

Upper radiator hoses carry coolant from the engine to the radiator, while lower radiator hoses deliver coolant from the radiator back to the engine, completing the coolant circulation cycle.

Coolant hoses are typically made from durable rubber compounds with reinforcements to withstand high temperatures and pressure fluctuations.

The cost to replace coolant hoses can vary depending on the number of hoses and the specific equipment but may range from $10 to $60 or more, not including installation.

Coolant hoses should be checked annually, and replacement intervals are usually around three to four years or as needed based on their condition.

Coolant hoses are situated in the engine compartment and connect the engine, radiator and other cooling system components.

Signs of wear, leaks, soft spots, engine overheating or visible damage on coolant hoses signal the need for replacement.

Vacuum hoses play a critical role in maintaining the proper pressure in your machine’s engine, as well as aiding in the pneumatic processes involved in some exhaust systems.

Vacuum hoses are commonly made from rubber or synthetic materials designed to handle vacuum pressure and resist deterioration.

The cost to replace vacuum hoses is generally lower compared to other types, ranging from $20 to $50 per hose, not including installation.

While vacuum hoses are more durable, they should still be inspected annually and replaced as needed due to wear and tear.

Vacuum hoses are routed through the engine compartment.

Rough idling, loss of power and an engine that won’t start are signs that vacuum hose may need to be replaced.

A/C hoses are part of the air conditioning system, transporting refrigerant to facilitate the cooling process inside the cabin.

A/C hoses are made from specialized rubber or thermoplastic materials that can withstand high-pressure refrigerant and strenuous temperatures.

The cost to replace A/C hoses in heavy equipment can range from $100 to $300 or more per hose (not including installation), depending on the complexity of the A/C system.

A/C hoses should be checked annually, and replacement intervals can vary but are typically around 5 to 7 years or as needed based on their condition.

A/C hoses are routed through the engine compartment and the cabin to connect the A/C compressor, condenser and evaporator.

Refrigerant leaks, visible damage or reduced cooling efficiency are signs of A/C hose issues. These signs may indicate your A/C hose needs to be replaced.

While simple in design, hoses play a complex and crucial role in ensuring the smooth performance of heavy equipment. If you’re looking for replacement hoses for your machine, look no further than the MechLink Shop.

Our OEM-powered parts catalog makes it convenient to find replacement hoses from a wide variety of manufacturers. Still can’t find the part you need? Reach out to one of our parts experts and get personalized assistance.

What is wet stacking and how do you prevent it?

January 8, 2026

The most common heavy duty air compressor problems and how to prevent them

January 8, 2026

A look at takeuchi equipment: your options and their advantages

January 7, 2026

Identifying hydraulic pump failure symptoms: what to know before hydraulic pump repair

January 7, 2026