— July 31, 2025

This blog highlights common issues in an excavator machine’s hydraulic system, including low pressure, leaks, overheating, and slow response. It provides solutions to maintain hydraulic excavators like JCB excavator, Tata Hitachi excavator, and CAT excavator. Regular checks ensure optimal performance of construction excavators, minimizing downtime and repairs. For maintenance tips, explore MechLink.

The hydraulic system is the heart of an excavator. It directs the flow of power for the excavator’s movement, lifting capability, and productivity. A malfunctioning hydraulic system means inefficient equipment, leading to delays in operations and increased maintenance costs. Hydraulic systems are among the most pressurized and continually loaded parts of the excavator’s work systems. Even a small fault in the hydraulic system can lead to huge failures.

Common hydraulic problems, such as low pressure, overheating, leaking, and unresponsive controls, can greatly impact productivity in hydraulic excavators. Such problems reduce efficiency and result in expensive repairs and more downtime, increasing the project schedule.

In this blog, we will cover several hydraulic system problems that an excavator can develop, their causes, and available solutions. Whether it’s hydraulic fluid leaks, slow operation, or overheating, knowing the causes of these problems can help operators maintain their machines and avoid unexpected breakdowns. For working without any disruptions and efficiently, the excavator needs regular maintenance and timely repairs. Now, let us get into the common hydraulic problems and their solutions.

The hydraulic system on an excavator is particularly important for its functioning. Any failure could lead to a drop in performance, costly repairs, and delays on the project. The following hydraulic problems are some of the most common seen in excavators, causes of the problems, and solutions to fix them.

The hydraulic system defines an excavator’s efficiency and performance and is at the same time one of the most easily affected components. Problems such as low hydraulic pressure, overheating, slow response, leakage, and jerky movements highly hamper production and incur downtime. However, upon prompt detection and a little maintenance, most of these issues can be reduced or avoided altogether.

Regular maintenance is indispensable for the hydraulic system of an excavator to remain under peak performance. MA maintenance routine including daily checks of hydraulic fluid levels, filters, hoses, pumps, and cooling systems will prevent small inconveniences from growing into catastrophic breakdowns. Operators should also adhere to the manufacturer’s recommendations regarding hydraulic oil selection, pressure-setting procedures, and air-bleeding procedures for maximum performance.

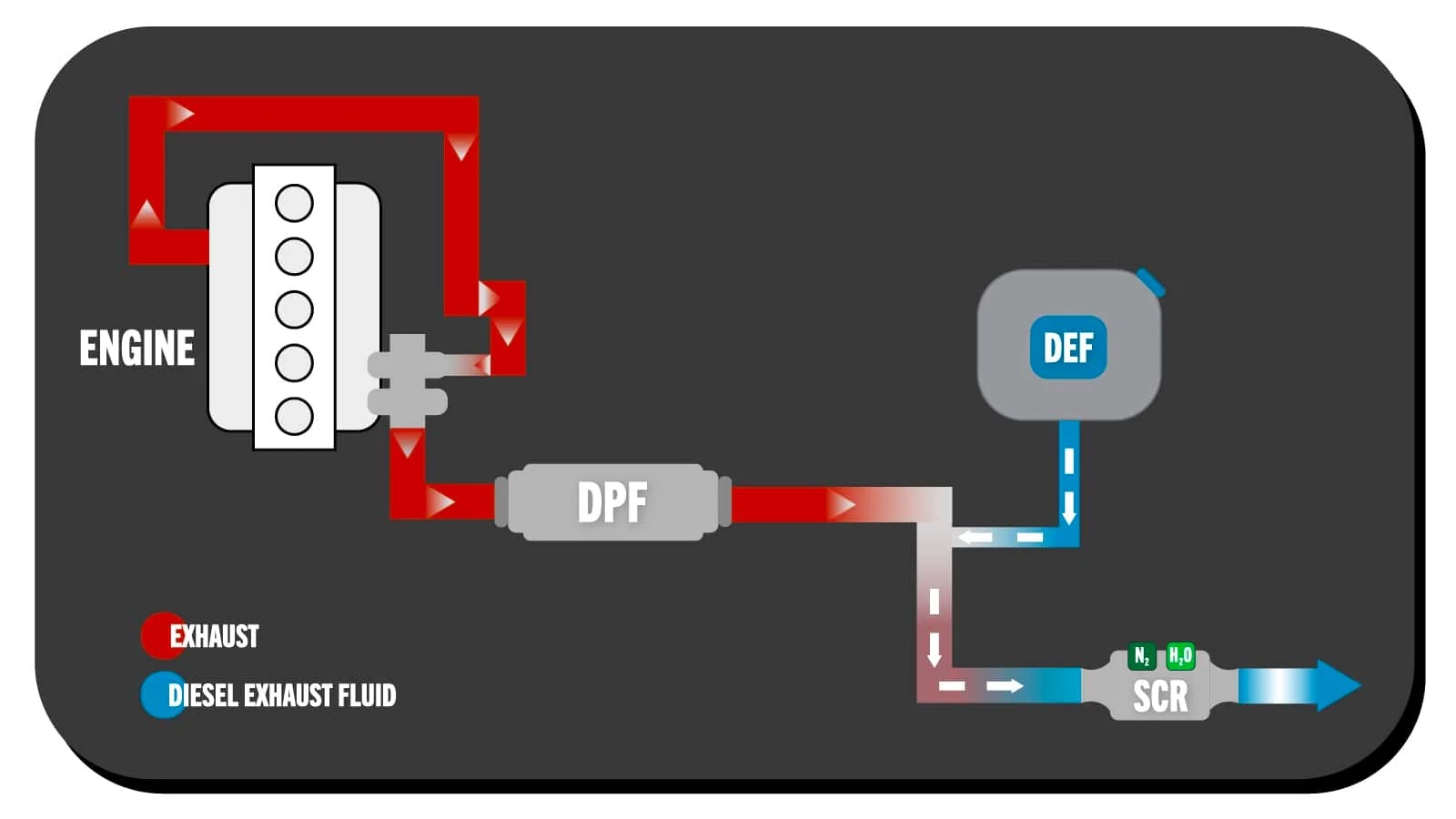

The role of diesel exhaust systems in construction equipment (with maintenance tips)

December 24, 2025

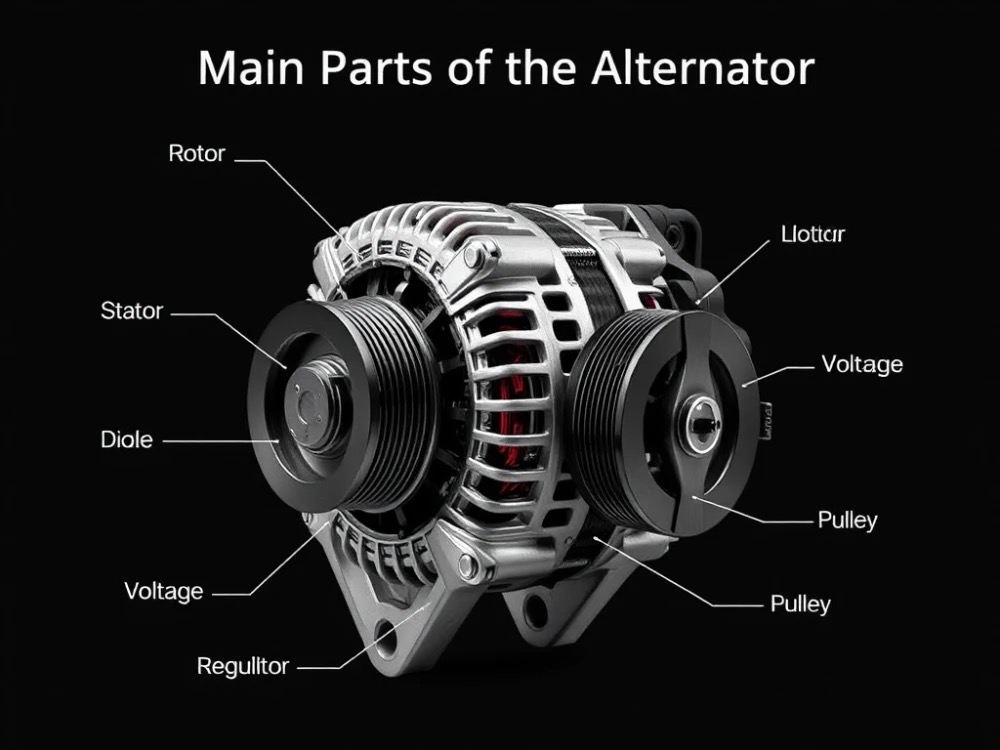

The crucial role of alternators in heavy equipment

December 24, 2025

The types of springs found in construction equipment and their hidden functions

December 23, 2025

Diesel fuel systems in heavy equipment: the impact of key components

December 23, 2025