— March 27, 2025

In the heavy equipment industry, fuel costs are a significant concern, often accounting for over 30% of total operating expenses. With fuel prices on the rise and the need to enhance operational efficiency, contractors, equipment traders, and rental companies are constantly seeking ways to optimize fuel consumption. MechLink offers a range of solutions to help you achieve this goal, with the 2022 Sany STC250E5 25t Truck Crane being a prime example of our fuel - efficient offerings.

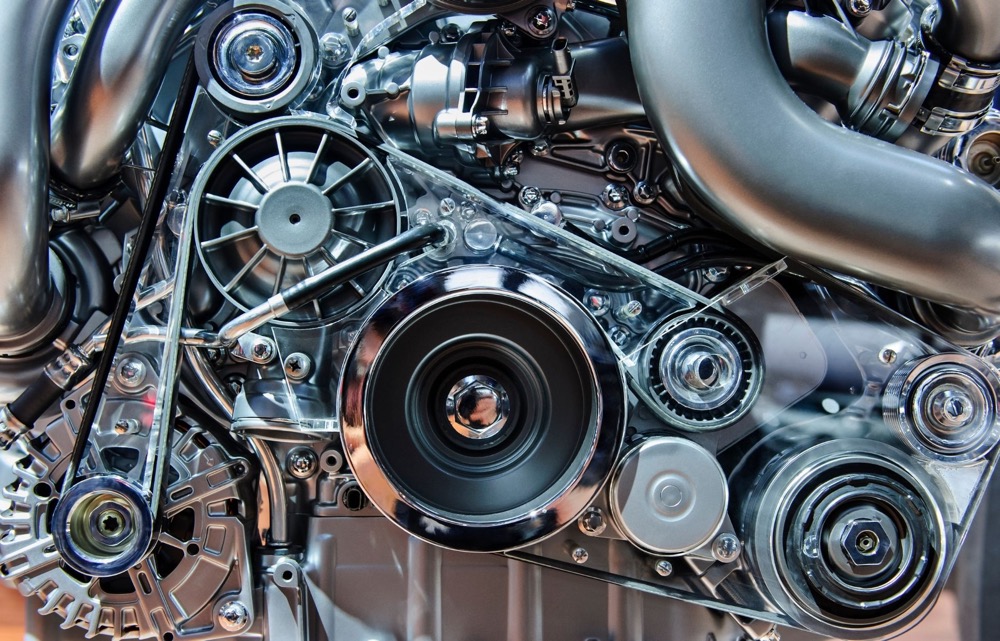

Modern heavy equipment like the 2022 Sany STC250E5 25t Truck Crane, available through MechLink, is equipped with advanced technologies for enhanced fuel efficiency. It features an engine with intelligent electronic control systems, similar to the Tier 4 Final engines in other high - end equipment. This system can precisely detect the crane's real - time workload. When lifting lighter loads or performing less - strenuous tasks, the system adjusts the fuel injection volume accordingly, reducing unnecessary fuel burn. During heavy - duty lifting operations, it ensures sufficient power output by optimizing the fuel supply. This dynamic adjustment of fuel injection based on the workload optimizes the combustion process, leading to more complete fuel combustion and better fuel efficiency.

Moreover, the 2022 Sany STC250E5 is integrated with MechLink - supported telematics systems. These systems act as the "brains" of the crane, collecting and analyzing data in real - time. They can monitor the crane's fuel consumption, allowing operators to identify any abnormal fuel - consuming situations promptly. If the crane shows a sudden increase in fuel consumption, the telematics system can quickly pinpoint whether it is due to engine malfunctions, improper operation, or other factors. By addressing these issues in a timely manner, unnecessary fuel waste can be avoided. MechLink's platform provides additional support in interpreting this data, ensuring that users can make informed decisions to optimize fuel usage.

The 2022 Sany STC250E5 lives up to its name with a nominal lifting capacity of 25 tons. This makes it suitable for a wide range of lifting tasks in construction projects. Whether it's hoisting pre - fabricated building components, such as medium - sized steel columns used in multi - story building construction, or moving construction materials like large concrete slabs on a construction site, the STC250E5 can handle the job with ease. Its lifting capacity remains stable across different working radii, ensuring reliable performance in various scenarios. For example, at a short working radius close to the crane's base, it can lift the full 25 - ton load, while at an extended radius, it still maintains a significant lifting capacity, which is carefully calibrated to meet industry - standard safety margins.

The crane is equipped with a powerful boom system. The main boom of the 2022 Sany STC250E5 has a length that can extend up to 40.5 meters. This extended boom length enables it to reach great heights and distances. In high - rise building construction, the crane can easily lift materials to upper floors. The boom's reach capabilities also make it useful for projects where access is restricted. For instance, in urban construction sites with limited space around the building, the long - reaching boom can reach over obstacles and place materials exactly where they are needed. Additionally, the boom's telescoping mechanism is designed for smooth and efficient operation, reducing the time and energy required for boom extension and retraction, which in turn contributes to fuel savings.

The 2022 Sany STC250E5 is designed for efficient operation with optimized operating speeds. The hoisting speed can reach up to 8 meters per minute. This relatively high hoisting speed means that it can complete lifting tasks more quickly, reducing the overall time the crane is in operation. Faster hoisting speeds not only increase productivity but also help in reducing fuel consumption. Since the crane spends less time idling or operating at partial capacity between lifts, less fuel is wasted. The slew speed, which determines how quickly the crane can rotate, is also carefully calibrated. A well - balanced slew speed allows the crane to position loads accurately without excessive movement, further enhancing efficiency and reducing fuel waste.

Under the hood, the 2022 Sany STC250E5 is powered by an engine with [engine power value] horsepower. This powerful engine is designed to provide sufficient torque for heavy - duty lifting tasks while also being fuel - efficient. Thanks to its advanced fuel injection system and intelligent engine management, as mentioned earlier, the engine can adjust its power output according to the actual workload. When the crane is performing light - duty tasks, the engine operates at a lower power setting, consuming less fuel. During heavy - duty operations, it ramps up power to meet the demand, but still maintains an optimized fuel - to - power ratio. This balance between power and fuel efficiency is a key feature of the STC250E5, making it an ideal choice for cost - conscious contractors.

Operators play a crucial role in determining the fuel consumption of heavy equipment. At MechLink, we offer operator training programs specifically tailored to our equipment, including the 2022 Sany STC250E5 25t Truck Crane. One of the key aspects of this training is to teach operators to avoid excessive idling. Idling is a major fuel - waster, and in some cases, it can account for up to 40% of the total engine running time. Our training programs emphasize the importance of turning off the engine when the crane will be idle for more than a few minutes, such as during breaks or when waiting for other work processes to be completed. This simple practice can save a substantial amount of fuel over time.

Another important aspect of our training is teaching smooth operation techniques. Aggressive driving behaviors like rapid acceleration and sudden braking not only increase fuel consumption but also put additional stress on the crane, leading to increased wear and tear. Operators are trained to accelerate gradually and brake smoothly when moving the crane. When starting the crane, a slow and steady acceleration allows the engine to operate more efficiently, consuming less fuel. Gentle braking reduces the energy loss associated with sudden stops. Additionally, operators are trained to plan their work routes and lifting operations in advance. This helps minimize unnecessary movement and reduces fuel consumption. MechLink's training programs ensure that operators are well - versed in these fuel - saving techniques, maximizing the efficiency of the 2022 Sany STC250E5.

Regular maintenance is essential for keeping the 2022 Sany STC250E5 25t Truck Crane in optimal condition and achieving good fuel efficiency. The fuel filter in this crane is a vital component. Over time, dirt, debris, and impurities in the fuel can accumulate in the filter. When the fuel filter becomes clogged, it restricts the flow of fuel to the engine. As a result, the engine has to work harder to draw in the necessary fuel, consuming more energy and fuel in the process. MechLink recommends following the manufacturer's guidelines for fuel filter replacement, which is typically at specific intervals based on the crane's operating hours.

Lubrication also plays a critical role. Using the correct type and viscosity of lubricating oil can significantly reduce friction between moving parts in the engine and other components of the crane. When there is less friction, the engine can operate more smoothly and with less resistance, thereby consuming less fuel. MechLink provides guidance on the best lubrication practices for the 2022 Sany STC250E5, including using the recommended lubricating oil and following the manufacturer - suggested oil change intervals. Regular checks of the oil level and quality are also emphasized to ensure that the crane is always operating with optimal lubrication, reducing friction and improving fuel efficiency.

Choosing the right heavy equipment for a specific task is crucial in reducing fuel consumption, and MechLink is here to help. The 2022 Sany STC250E5 25t Truck Crane is an excellent choice for a variety of lifting tasks. Its design and capabilities are well - suited for medium - to - large - scale construction projects. For example, in building construction or infrastructure development, this crane can efficiently handle the lifting of construction materials such as steel beams and concrete blocks.

The 2022 Sany STC250E5 is carefully engineered to have an appropriate power - to - weight ratio. This means that it can perform its tasks without being over - powered or under - powered for the job at hand. An over - powered crane would consume more fuel than necessary, while an under - powered one would struggle to complete the task, also resulting in increased fuel consumption. MechLink's team of experts can assist you in evaluating your project requirements and determining if the 2022 Sany STC250E5 is the right fit. We also ensure proper matching of equipment components, as a well - matched powertrain in the crane allows for smooth power transfer and efficient operation, further optimizing fuel consumption.

Reducing the fuel consumption of heavy equipment is achievable with MechLink's comprehensive approach. By leveraging advanced technology in equipment like the 2022 Sany STC250E5 25t Truck Crane, providing operator training, emphasizing regular maintenance, and ensuring proper equipment selection, companies can cut down on fuel costs, improve overall operational efficiency, and contribute to a more sustainable operation. Explore MechLink's offerings today and start optimizing your heavy equipment fleet for better fuel efficiency.

A guide to sprockets in construction equipment: types, functions, maintenance, and more

December 3, 2025

Key components of an excavator arm and how to maintain them

December 3, 2025

Final drive maintenance tips: preventing issues before it’s too late

December 2, 2025

Engine cooling system maintenance for heavy equipment 101

December 2, 2025