— August 27, 2025

This blog offers a complete guide to motor grader maintenance for breakdown prevention. Learn daily checklists, service schedules, and parts replacement tips to keep your motor grader machine in top shape. Whether you use a CAT, CASE, or Tata Hitachi grader, timely diagnostics, OEM parts, and operator training ensure long-term performance and reduced downtime. Visit MechLink for expert support.

Modern times have seen a surge in the infrastructure and construction industry, and with that, there has been an increase in demand for construction equipment. Among the construction equipment is the motor grader. A motor grader is one of the most essential machines in any large-scale construction or road project. However, it can easily break down without proper care, increasing your downtime and costs in the operations. This blog is your complete guide to motor grader maintenance, where we will explain all the motor grader service tips and insights on how to maintain a motor grader effectively.

We should take preventive measures not only to avoid downtime, but effective motor grader maintenance is also required to ensure long-term performance, enhance cost-efficiency, and safety of the machine. Here’s why motor grader breakdown prevention should be a top priority:

Whether you’re managing a single grader or a fleet, adopting a solid maintenance plan protects your investment and improves ROI significantly.

A motor grader’s daily maintenance checklist should be part of your routine before and after operation. Here’s what to include:

Regular checks are a small effort that can go a long way in motor grader breakdown prevention.

Every motor grader manufacturer, be it CAT, CASE, or MechLink Construction Equipment, provides a thorough service interval guide that must be followed to ensure that the machine stays in tip-top shape.

A well-structured motor grader maintenance schedule helps you:

A scheduled maintenance program ensures that:

Keeping tip: Maintain a service logbook or use fleet management software to keep track of the service history.

Understanding common motor grader problems will help you identify the causes of breakdown. Hence you can easily take preventive measures. Some frequent issues that are common problems in a motor grader are:

Recognizing these problems early helps in timely repairs and reinforces motor grader preventive maintenance.

The engine and hydraulic system of a motor grader are the most important parts. They should be thoroughly checked at regular intervals to ensure that there is no fault in the machine. If they are not regularly maintained, then there is a high risk of failure and increased downtime.

Here’s how to maintain them effectively:

Whether you’re operating a Komatsu or an ACE motor grader, these universal practices will maximize efficiency and reliability.

Operators act as the first line of defense when it comes to the breakdown of machines. Investing in the training of operators for machinery means improved health of machines and lower servicing costs.

Prepare a customized servicing guide or SOP (Standard Operating Procedure) that includes:

This practice is one of the most cost-effective motor grader service tips. Brands like Mahindra Construction Equipment and LiuGong also offer operator training programs. Make sure your team stays updated.

It is very necessary to conduct regular motor grader troubleshooting and diagnosis for proper running of the machine. In the case of regular troubleshooting using proper diagnostic tools, internal systems are detected for problems, especially those that are not detectable by physical inspections.

The following diagnosis should be done regularly to avoid the following tests must be considered:

These checks are key to motor grader breakdown prevention and help avoid costly overhauls later.

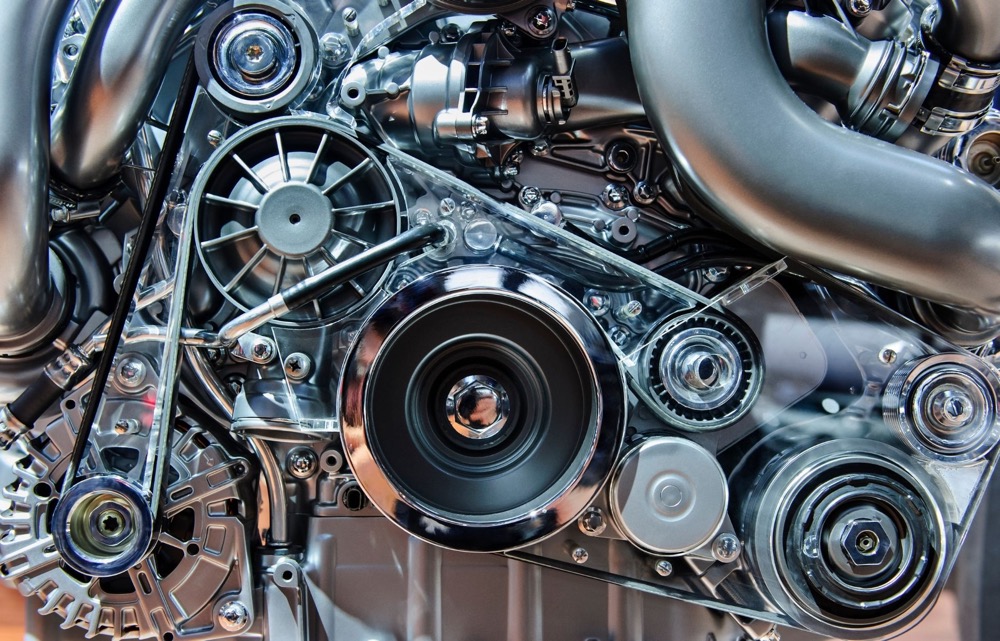

Ignoring wear and tear is one of the common mistakes that is responsible for the unexpected breakdown of graders. One of the simplest ways to prevent motor grader breakdown is to replace parts like blades, filters, and belts on time. Delaying replacement can cause stress on other components. The following are some of the most commonly utilized parts that need to be inspected:

Manufacturers like BEML, ACE, and Tata Hitachi offer OEM parts that fit perfectly and last longer. Always opt for genuine parts to extend motor grader life.

While daily checks and operator training are essential, professional servicing at authorized centers offers deeper inspection and specialized care.

What expert servicing includes:

Manufacturers like CAT and CASE provide bundled AMC packages that include inspections, parts replacement, and priority support—all at a fixed annual cost.

Preventing motor grader breakdown is not merely a matter of fixing issues—it’s a matter of creating a habit of smart, preventive maintenance. By following a regular maintenance schedule, periodic diagnostic tests, periodic replacement of worn components, and well-trained operators, you can greatly reduce downtime and extend the life of your machine by years. Working with trusted brands such as CAT, CASE, BEML, and Tata Hitachi for OEM components and professional service guarantees optimum performance and peace of mind. Whether you operate a fleet from Komatsu, LiuGong, or Mahindra Construction Equipment, following this guide will help you extend motor grader life and get the best ROI on your machines.

For more expert advice and genuine equipment listings, head over to MechLink now.

A guide to sprockets in construction equipment: types, functions, maintenance, and more

December 3, 2025

Key components of an excavator arm and how to maintain them

December 3, 2025

Final drive maintenance tips: preventing issues before it’s too late

December 2, 2025

Engine cooling system maintenance for heavy equipment 101

December 2, 2025