— March 27, 2025

When you're in the market for a used excavator, you might be well - versed in what you're looking for, what inspections to conduct, and what price range is reasonable. But if you've just started your search and have some lingering uncertainties about finding the ideal excavator for your needs, this concise buying guide is here to assist.

Read on for some straightforward tips to aid you in your search and ensure that the excavator you select is the perfect fit for you and your work.

The initial step most people take when looking for a used excavator is to narrow down their search based on the size that best suits their work. However, this is often easier said than done. Owners typically want an excavator that can handle a wide variety of jobs. An excavator that's too small may struggle to keep up with other equipment on the site, while an oversized one can be cumbersome to operate in tight spaces or inefficient for many tasks.

Determining the optimal size of the excavator for your work involves evaluating the nature of the jobs you usually undertake and aligning your search accordingly. Keep in mind that your investment in the machine should yield a return on investment. So, consider jobs that can boost your ROI. For example, if a larger or smaller machine can increase your earnings, this should influence your decision.

Take the 2021 Sany SY215C Excavator, for instance. It offers a balanced size for many medium - scale projects. With some research, you can quickly zero in on a used excavator like the SY215C that meets your requirements.

An excavator depends heavily on a well - functioning and well - maintained hydraulic system, even more so than many other construction equipment. Thus, extra care must be taken to inspect it thoroughly. During your inspection, closely examine the main hydraulic pump, all cylinders, and each of the final drives for leaks. A minor leak might seem like a quick fix, but it could also signal neglect or underlying system problems.

Examine the hydraulic fluid (you could even have it tested) to detect any issues in the hydraulic system. Rubbing the fluid between your fingers to check for grit or debris can help you identify system troubles or a lack of proper maintenance. Since a tracked excavator's movement is powered by its final drives, it's crucial to check the fluid in the final drives for signs of wear in the planetary gears or other components. In the case of the 2021 Sany SY215C Excavator, a well - maintained hydraulic system is key to its efficient operation.

The slewing ring, located at the connection between the excavator house and the car body, enables the smooth and independent rotation of the house. This vital component is in constant use whenever the house spins and will eventually wear out and require replacement, which can be a costly repair. Understanding the slewing ring's condition when you buy the machine can help you determine a fair price.

To test the slewing ring, slowly rotate the house and watch for play, wobbling, or any abnormal movement. Ensure the movement is smooth and consistent. If possible, inspect the grease inside the ring for debris or grit, as this could indicate that parts are wearing out due to friction within the bearing.

Any joint or pivot point on an excavator is prone to increased friction, wear, and part - related problems. An excavator's versatility comes from its wide range of motions, but at each movement point, multiple parts must work together seamlessly. When inspecting the machine, check these points (and even operate them through their motions) for signs of failure, binding, misalignment, or uneven movement.

Since the bucket, stick, boom, and other parts' movement is made possible by the hydraulic cylinders on the excavator, check the cylinders for leaks, examine the chrome for pitting or rust, and look for visible bends or misalignment. Replacing a cylinder isn't overly complex, but it's better to be aware of any potential issues in advance.

While some rust on a used excavator bucket is normal, make sure that excessive wear on the teeth and cutting edges won't affect the excavator's efficiency. Also, look for patches or welds that suggest the bucket has been repaired. Repairs aren't necessarily a deal - breaker, but ensuring they were done correctly and professionally can help you gauge the bucket's remaining lifespan.

The undercarriage of an excavator is often the most expensive part to repair, regardless of the machine's overall condition. Paying close attention to the undercarriage can give you a better idea of the extent and cost of future maintenance. Besides assessing the overall condition of the tracks, ensure that the tensioners and track springs are applying proper tension, and that the idler wheels and roller wheels aren't overly worn or misaligned.

The tracks of an excavator are powered by two final drives. Although these drives are designed to withstand long - term, heavy - duty work, the gears inside can deteriorate over time. While you probably won't be able to open them up to inspect the gears directly, you can check the fluid for signs of contamination and test them to ensure the machine moves smoothly without any jerks or delays.

The cab of a used excavator is often overlooked during the search, but a cab with faulty safety equipment, worn - out controls, or other issues can pose risks to operator safety and comfort. Adding an excavator to your fleet should be met with enthusiasm by operators, and cab problems can dampen their experience. Taking the time to identify cab issues and plan repairs in advance can ease the new machine into your operations and ensure it's ready for work as soon as it arrives at the jobsite.

Ideally, the machine you purchase will perform optimally for a long time. But eventually, every part will wear out, and you'll need a replacement. During your search, identify commonly replaced or rebuilt parts and determine their availability to avoid future supply problems.

As the machine ages, finding replacement parts can become more challenging. Choosing a machine from a popular manufacturer like Sany, such as the 2021 Sany SY215C Excavator, can help you avoid lengthy searches and high costs. At MechLink, we understand the importance of part availability and can assist you in sourcing the right parts for your excavator.

Once you've found the perfect used excavator for sale, you'll need to negotiate a price that works for both you and the seller. Researching similar machines can give you a starting point for negotiations. However, in 2022, supply chain issues and other factors have led to a shortage in the market and increased demand for used construction equipment.

To accurately evaluate the specific machine, create a checklist, mark the condition of the parts mentioned above and other crucial components, and then compare this to the repair costs. This approach can help you and the seller reach an agreement on the best price for the machine.

If the used excavator you're interested in is nearby, it's best to see the machine in person to closely inspect the important parts. But if it's too far away, request numerous pictures, including close - ups of critical components, and even a video of the machine running and in operation. In today's digital age, a reputable seller, like those associated with MechLink, will have no problem providing this digital evidence of the machine's condition and will be happy to ensure that both parties agree on its state.

With these simple inspection tips, you'll be one step closer to finding the perfect used excavator that will serve you well for the long term. If you need replacement parts, either to bring your newly purchased excavator up to your standards or for future repairs, MechLink is here to help. As a leading provider of excavator parts, our Parts Specialists can help you find the right replacement part and get you back to work quickly. When you contact a MechLink Parts Specialist, they'll connect you to our extensive inventory of new, used, and rebuilt excavator parts, as well as our vast network of parts suppliers. Just reach out to us.

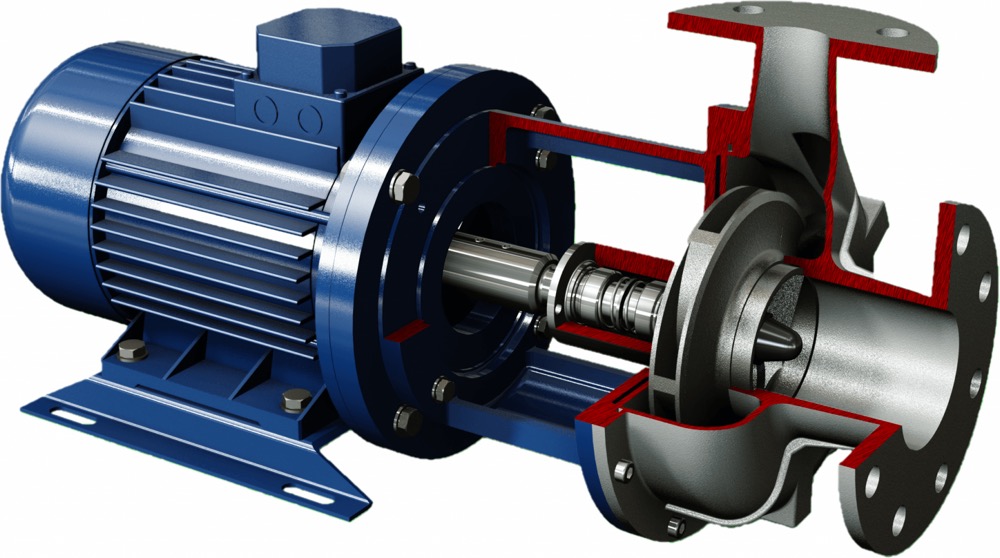

Centrifugal pumps 101: types, key components, and applications in cons

January 28, 2026

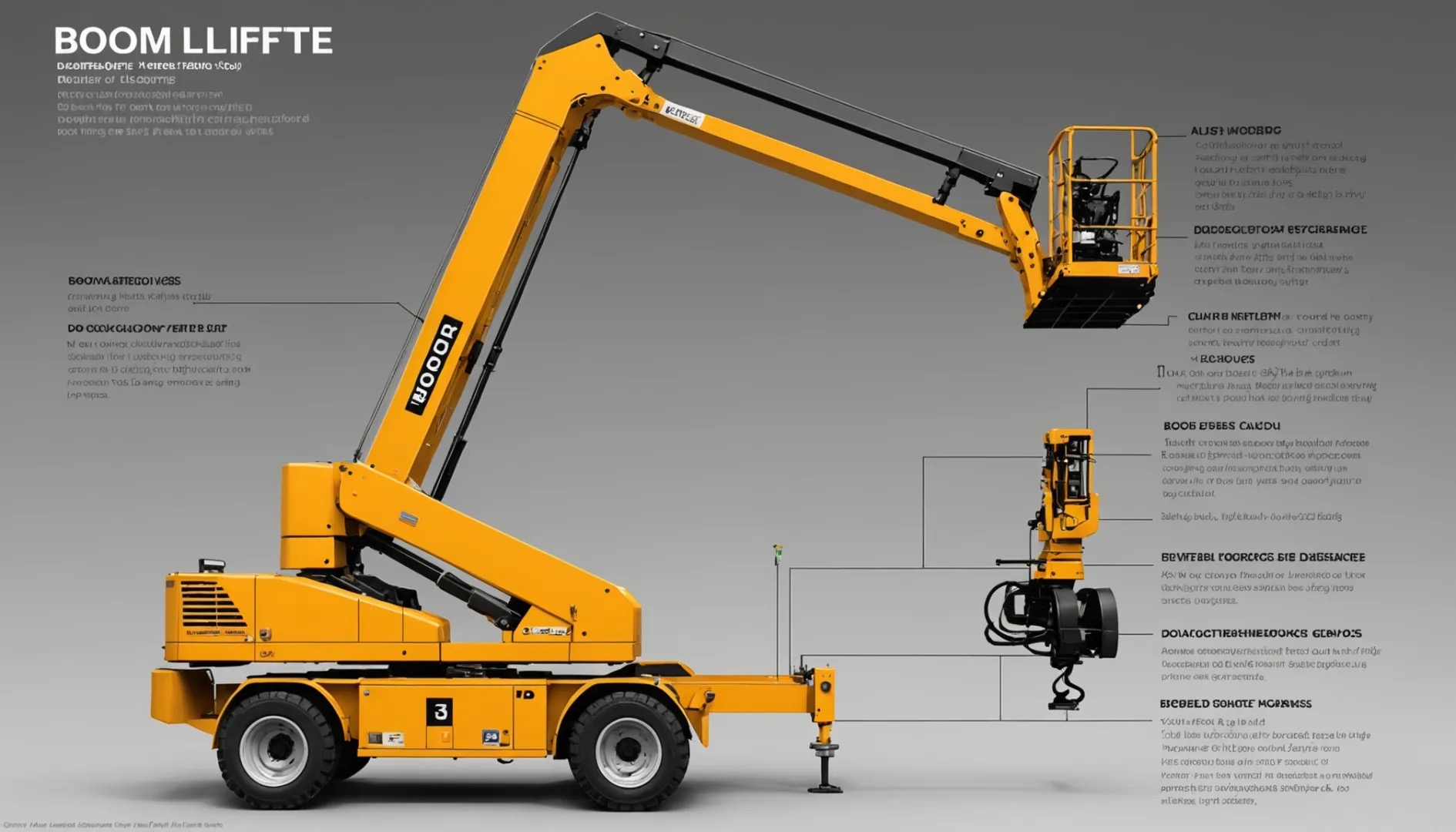

An overview of the most popular and most underrated boom lift parts

January 28, 2026

The benefits of using a seal kit for heavy equipment maintenance

January 27, 2026

How diesel fuel pumps keep your heavy equipment running smoothly

January 27, 2026