— December 30, 2025

Transmission systems play a critical role in directing and controlling the power output of heavy equipment engines. These intricate systems are designed to transfer power from the engine to a machine’s wheels or tracks, enabling controlled and effective movement.

These systems generally function by altering gear ratios and controlling how much power is transmitted at any given time. This capability is essential, allowing operators to control the machine's power output and speed according to the task at hand, whether it's moving heavy loads or performing precise maneuvers in confined spaces.

The transmission system includes interconnected components that work in tandem to ensure efficient operation. This may include components such as gears and shafts, the clutch, the torque converter and transmission fluid lines.

There are several different types of transmissions you’re likely to encounter in heavy equipment. These include automatic transmissions, hydrostatic transmissions and powershift transmissions.

A thorough understanding of the transmission system is critical for maintaining the longevity and functionality of heavy equipment. In this article, we’ll provide an overview of heavy equipment transmissions, providing you with the information you need to properly maintain the machines in your fleet.

Each heavy equipment transmission type is associated with certain pros and cons, including common maintenance issues. Here are some of the most common maintenance issues encountered in heavy equipment transmission systems.

Recognizing the early signs of transmission problems in heavy equipment is crucial. Ignoring these signs can lead to more severe issues, potentially resulting in costly downtime and repairs. Here are key indicators that suggest a transmission issue in heavy equipment.

One of the most noticeable signs of a transmission problem is unusual noises. These can range from grinding and clunking sounds when shifting gears to whining or buzzing noises during operation.

If operators experience difficulty in shifting gears, such as the transmission refusing to go into gear or showing hesitation, it is a clear sign of a problem. This could be due to a variety of issues including low fluid levels or damaged/misaligned gears.

Excessive or abnormal vibrations during the operation of heavy equipment can be a sign of transmission troubles. These vibrations may be felt through the seat or controls and can indicate misalignment, wear or damage to transmission components.

Transmission overheating is a critical issue and often manifests as high-temperature readings on the equipment's dashboard or a burning smell. Overheating can be caused by low or degraded transmission fluid, clogged filters or excessive strain on the transmission due to heavy loads or harsh operating conditions.

In tracked vehicles like excavators or dozers, problems with track engagement can be a direct result of transmission issues. Difficulty in moving forward or backward, or uneven movement between tracks, can indicate a problem within the transmission system that is affecting power distribution to the tracks.

Visible signs of leaking transmission fluid are a clear indicator of a problem. Transmission fluid is typically red or green and will appear under the machinery when there is a leak. Leaks can be due to damaged seals, loose connections or cracks in the transmission casing.

Deciding between replacing or repairing a heavy equipment transmission depends on factors such as the extent of damage, cost implications and equipment age.

Repair is often preferable for minor issues or relatively new machinery, as it can be more cost-effective. However, if the transmission has extensive damage, repeated failures or the equipment is old, replacement might be more economical in the long term.

Replacement ensures reliability but comes with higher initial costs. In contrast, repairs have lower upfront costs but can accumulate over time, especially with older models.

Regularly scheduled transmission maintenance includes checking and replacing transmission fluid, inspecting seals and filters for damage or clogs, and monitoring for leaks or unusual noises.

Modern technology aids in this process through advanced diagnostic tools and monitoring systems. These systems can track transmission performance in real-time, alerting operators to potential issues before they become severe. By adhering to a comprehensive preventive maintenance schedule, operators can significantly reduce the risk of transmission failures and maintain operational efficiency.

Maintaining the health of your machine’s transmission system is critical to keeping your machine operating efficiently. By implementing a thorough preventive maintenance program that addresses the needs of your machine’s transmission system, you can improve operator efficiency and reduce maintenance costs.

The MechLink Shop has OEM and aftermarket parts available for preventive maintenance and part replacement needs. Explore our extensive online parts catalog to find components for your fleet. Or, reach out to our parts experts and get personalized assistance.

Skid steer overheating: causes and effects

December 30, 2025

What is a grease fitting? the functions and maintenance of zerks in heavy equipment

December 29, 2025

Slab or rough terrain scissor lift? choosing one based on maintenance & more

December 29, 2025

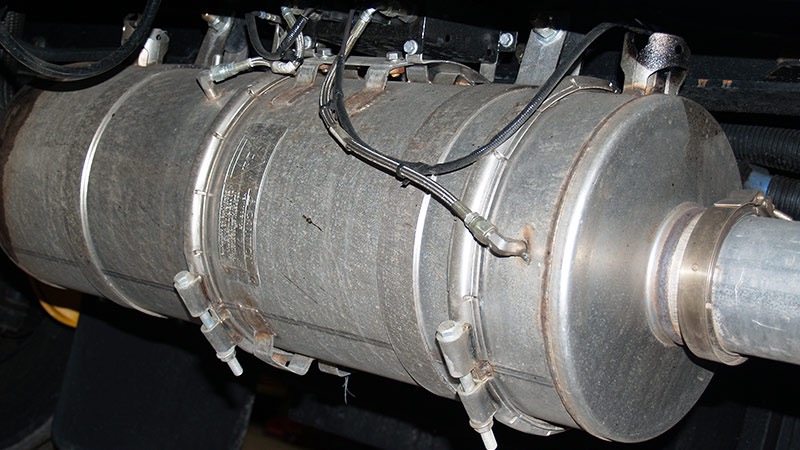

What is a diesel particulate filter and how do you maintain it?

December 26, 2025