— November 24, 2025

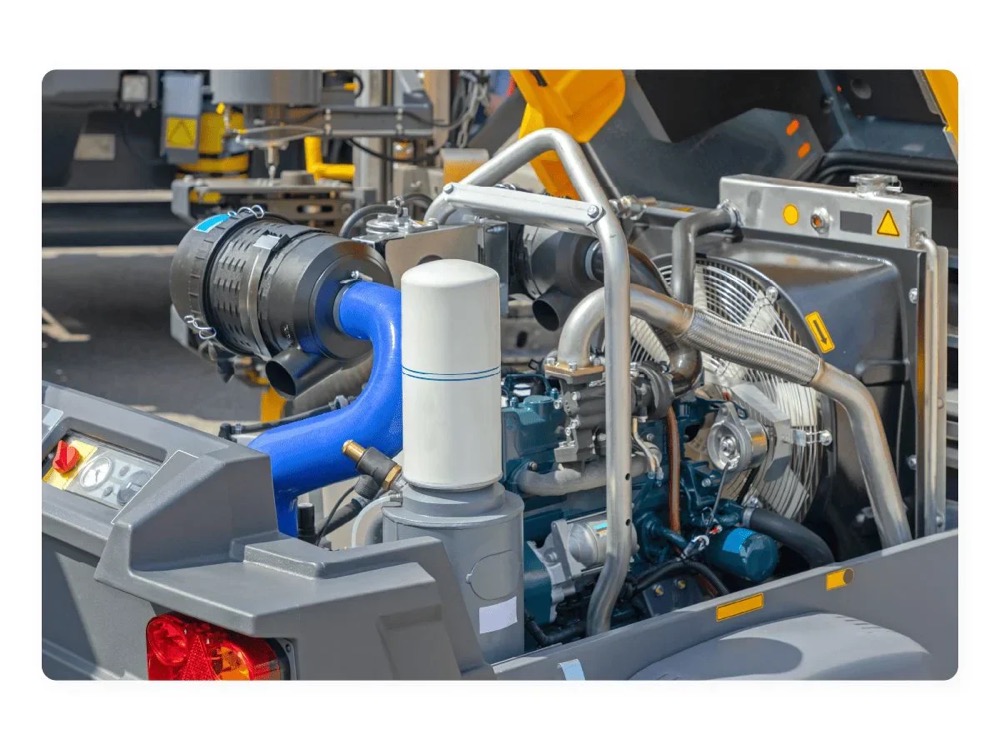

At the heart of every heavy construction machine lies a powerful hydraulic system. These systems are responsible for transferring power and force to execute a wide array of tasks with precision and brute strength.

The nature of hydraulic systems allow for a seamless transmission of force, reduced mechanical wear and the ability to amplify power instantaneously. It is this hydraulic muscle that’s revolutionized the landscape of heavy construction, making it a fundamental aspect of modern heavy equipment machinery.

As the complexity of heavy equipment continues to advance, hydraulic systems evolve in parallel, embracing new technologies to meet the demands of a rapidly changing industry. Understanding these hydraulic systems and effectively maintaining them is a responsibility no fleet manager or heavy equipment operator can afford to overlook.

In this guide, we’ll delve into the inner workings of hydraulic systems found in heavy construction equipment. By understanding the function of hydraulic systems and implementing preventive maintenance practices, fleet managers can ensure optimal performance, an increased lifespan and enhanced safety for their fleets.

Like all intricate systems, hydraulic systems require attentive care to ensure their reliability and longevity. Implementing an effective preventive maintenance plan for your machine’s hydraulic system is key to keeping your fleet on the job and minimizing downtime.

A neglected hydraulic system will result in severe consequences for the health of your machine. Leaking seals, contaminated hydraulic fluid or worn-out components can cause a loss of power, decreased machine control and total system failure.

The cost of repairs and downtime resulting from such negligence can dwarf the expenses of routine maintenance, making a preventive maintenance plan a wise investment.

When your machine’s hydraulic system goes unmaintained, it may degrade and start to break down. Here are the most common signs that your hydraulic system is failing:

There are several steps operators can take each day to ensure that their machine’s hydraulic system is working properly. Here are some critical daily tasks for maintaining your machine’s hydraulic system:

Your machine’s hydraulic fluid, or oil, plays a vital role in the efficiency and longevity of the hydraulic system. Keeping this critical fluid clean is not only a matter of routine maintenance, it is the key to unlocking optimal performance in your machine.

One of the biggest threats to your machine’s hydraulic fluid is contamination. As you operate your machine, debris and other contaminants may make their way into the hydraulic system through small clearances around cylinders or hose fittings.

Once inside the hydraulic system, abrasive contaminants such as silica may begin to disrupt the function of the system and degrade vital components like seals and gaskets. Hence, it is extremely important to maintain your machine’s hydraulic fluid and filters.

Signs that your machine’s hydraulic fluid has become contaminated include:

To minimize contamination of your machine’s hydraulic fluid, there are a few important steps you can take:

In addition to these maintenance practices, you may occasionally need to flush or bleed the hydraulic system. Flushing involves removing the old hydraulic fluid and replacing it with new fluid, while bleeding involves removing air from the system.

Ignoring initial symptoms or neglecting routine hydraulic system maintenance may seem like a cost-saving measure in the short term, but the consequences can be far-reaching and expensive down the road.

A neglected hydraulic system is a ticking time bomb that can lead to significant equipment downtime, costly repairs and, in the worst-case scenario, complete machine failure during critical operations.

By following maintenance best practices, operators and fleet managers can extend the life of their machines’ hydraulic systems and prevent costly breakdowns.

The MechLink Shop is a convenient place to solve all your hydraulic system needs. Our online parts catalog offers a wide range of OEM and aftermarket hydraulic system components, like filters, sealing components and more. Can’t find the part you’re looking for? Contact one of our parts experts and get personalized assistance.

What is wet stacking and how do you prevent it?

January 8, 2026

The most common heavy duty air compressor problems and how to prevent them

January 8, 2026

A look at takeuchi equipment: your options and their advantages

January 7, 2026

Identifying hydraulic pump failure symptoms: what to know before hydraulic pump repair

January 7, 2026