— November 27, 2025

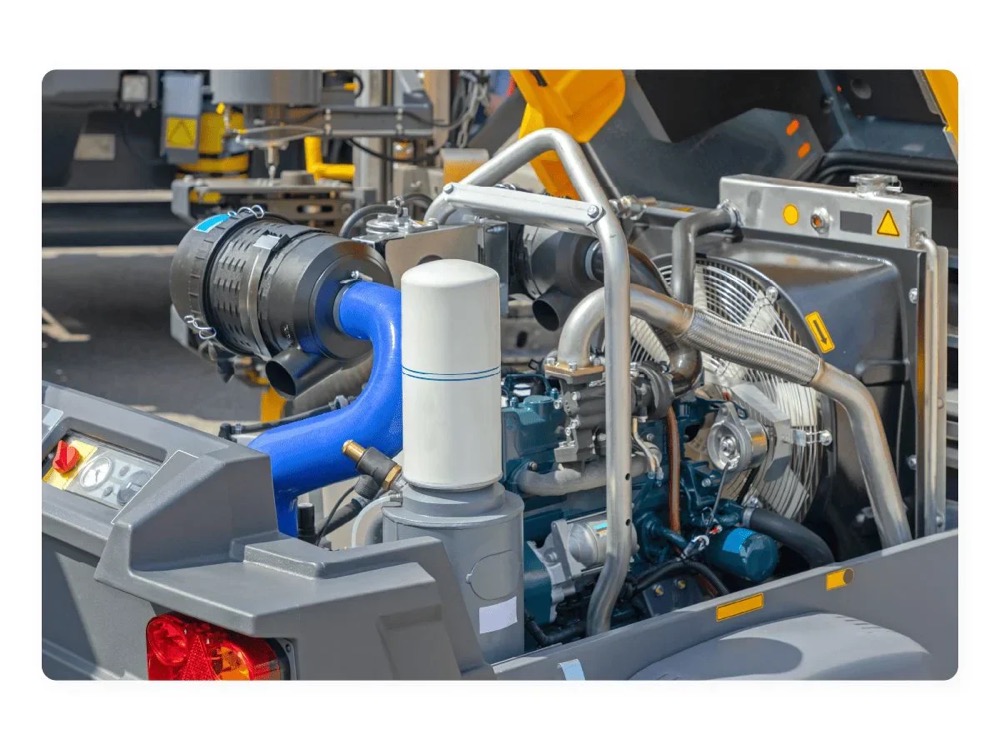

Modern heavy equipment relies on a complex system of fluids to operate efficiently. DEF, diesel fuel, engine oil, hydraulic fluid and other fluids enable machines to perform incredible feats of power and handle complex tasks with ease.

When any one of these vital fluids starts to leak, loss of power, system failures and breakdowns are just around the corner. Unfortunately, it isn’t always easy to tell when a leak is occurring. It can be equally as difficult to find where the leak is coming from.

Sometimes, the only indication that a machine is leaking is a puddle of fluid under the machine. Other times, you may not notice any fluid outside the machine, and the only indication of a leak is a loss of power or some other malfunction.

In this guide, we’ll go over the common types of fluid leaks that affect heavy equipment. We’ll provide you with the warning signs you need to look out for to spot a leak before it becomes problematic. Understanding the types of leaks common in heavy equipment and their associated symptoms can help you avoid costly breakdowns and unnecessary downtime.

While it isn’t always easy to identify a leak in heavy equipment, there are a few signs to look out for.

Depending on the type of fluid leaking from your heavy equipment, you may notice the leak comes from a particular location on the machine, involves a particular smell or causes certain symptoms while operating the machine.

Here are the most common types of leaks in heavy equipment and how to identify them:

Diesel fuel is combusted by the machine’s engine to supply power to the machine. The most common way to identify a diesel fuel leak is by a strong odor of diesel around the equipment.

Engine oil is responsible for lubricating engine components like pistons, bearings and cylinders. An engine oil leak is usually spotted by observing oil stains or puddles under the equipment.

Hydraulic fluid leaks are typically first noticed when a machine loses power. Leaks in high pressure hydraulic hoses can cause lethal injuries to operators if not handled with care, so it’s important to take precautions when searching for this type of leak.

While some machines require hydraulic fluid, some machines take hydraulic oil. Like hydraulic fluid leaks, a decrease in hydraulic system performance and visible fluid on components can indicate a hydraulic oil leak.

DEF plays a critical role in the exhaust system, reducing the amount of nitrogen oxides emitted. DEF leaks are usually identified by a noticeable decrease in DEF levels and white stains near the DEF tank.

Coolant helps maintain the temperature of your machine’s engine. Frequently, coolant leaks are identified by visible coolant puddles or stains, along with potential engine overheating.

While it isn’t possible to prevent all leaks, there are some steps you can take to make sure they occur less frequently. By implementing a preventive maintenance program that addresses the needs of your machine’s fluid-based systems, you can reduce breakdowns and downtime.

Here are some essential leak prevention measures to include in your preventive maintenance program:

When leaks do occur, it’s helpful if you’re prepared to treat them promptly. It’s always a good idea to have extra seals, gaskets, hoses, filters, hose clamps and tools on hand.

Unexpected leaks can cause your heavy equipment to malfunction, leading to breakdowns and costly downtime. By understanding common types of leaks and how to spot them, you can avoid these pitfalls and keep your machines on the job.

The MechLink Shop sells OEM and aftermarket hoses, seals and other parts that can help you address leaks and related issues. Our online parts catalog makes it easy to shop for parts and get the components you need. Can’t find what you’re looking for? Reach out to one of our parts experts to get personalized assistance.

What is wet stacking and how do you prevent it?

January 8, 2026

The most common heavy duty air compressor problems and how to prevent them

January 8, 2026

A look at takeuchi equipment: your options and their advantages

January 7, 2026

Identifying hydraulic pump failure symptoms: what to know before hydraulic pump repair

January 7, 2026