— July 23, 2025

Lifting loads with an excavator machine demands precision, safety, and the right practices. This blog outlines key safety checks, proper load handling, and common mistakes to avoid while operating machines like JCB excavators, Tata Hitachi excavators, and hydraulic excavators. For expert guidance and the best excavator price in India, visit MechLink today.

Did you know that lifting and moving heavy loads using an excavator involves not only raw power but also precision and safety? Excavators are the fundamental machines in the construction and excavation industry, and they are most often used in lifting and transferring large, heavy items. Improper lifting can result in accidents, damage to equipment, and delays that amount to increased operational costs.

This blog specifically goes into the key safety tips observed in lifts and hoists using excavators. The machine’s lifting capacity will be understood, the essential pre-lift checks, and the lifting techniques. It will be discussed here everything you need to know about their safety and efficiency while operating. So, you can indeed make the most out of productivity without risking so much on the job site.

Excavators are machines that possess several attributes and can perform a particular task – lifting and moving loads. The fundamental mechanics applied when using an excavator for lifting are hydraulics used to operate the boom, arm, and bucket of the machine. The operator must locate the load, lift it, and move it to the desired location using the components mentioned above, the hydraulic system, in this case, being of great importance as it provides the required force to lift the heavy materials and control their movements with precision.

Excavators are used to lift a wide range of materials and objects. Common loads lifted include construction debris, soil, and rocks, as well as pipes and in some cases, even large structural components such as steel beams or concrete blocks. As a result, excavators can be found lifting almost every conceivable object: from the smallest pea stones to massive steel girders, they do all and everything in between.

It is a very simple process between the boom, arm, bucket, and hydraulic system. Boom extends and raises the arm that is joined to the bucket to lift the load. The bucket then loads or picks up the material either by grappling or scooping it. These components are all actuated by the hydraulic system, providing force to safely lift heavy loads and move them. Knowing how these components work together is essential when undertaking safe and efficient lifting operations.

Before every lifting operation, a set of thorough checks has to be carried out. This is to ensure that both the excavator and the operator are in readiness for the job.

These include considerations for both extremes of the weather; they can cause high winds or rain or even storms with both extremes impacting lifting activities. Winds can sway loads or generally affect the stability of loads, especially when lifting. Weather conditions should be evaluated before proceeding, and lifting should cease in dangerous weather conditions for everyone on-site.

Some mistakes involved in operating an excavator can easily disrupt safety and efficiency.

In summary, safe lifting with an excavator should be maintained for the safety of the operator and efficiency in operation. Operators can ensure smooth and incident-free operations by understanding lifting capacities, conducting pre-lift checklists, adhering to safety tips, and avoiding common mistakes. Remember that communication and equipment are vital for successful lifting operations.

Visit MechLink for more excavator listings, equipment options, and safety tips that can support your operations.

Therefore, by following these safety tips and best practices, excavator operators can ensure that lifting tasks are performed without any incidents in a safe, efficient manner.

The role of wiring harnesses in construction equipment

January 22, 2026

Compact track loaders vs multi terrain loaders: how do they differ?

January 22, 2026

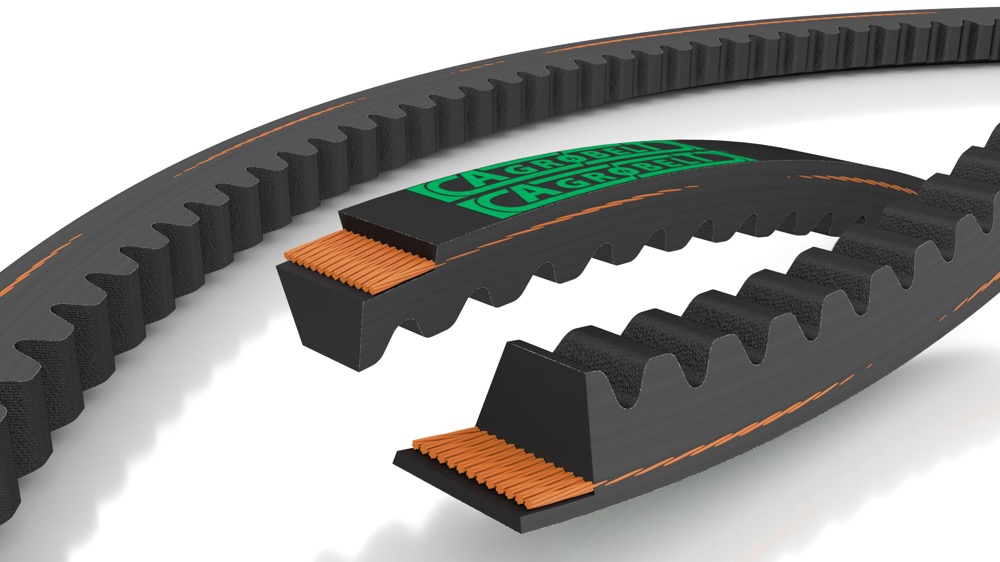

The role of v-belts in construction equipment: what you need to know

January 21, 2026

Boom lift safety: understanding the hazards and how to avoid them

January 21, 2026