What if a short, well-planned window could reset your fleet’s reliability—and your parts budget? On many Thai job sites, downtime is a chain of small delays: a late seal kit, a missing document, a second stoppage. This limited-time campaign is built to break that cycle with verified SANY genuine parts, predictable delivery windows, and a voucher loop that rewards planning—not one-off deals.

What if a short, well-planned window could reset your fleet’s reliability—and your parts budget? On many Thai job sites, downtime is a chain of small delays: a late seal kit, a missing document, a second stoppage. This limited-time campaign is built to break that cycle with verified SANY genuine parts, predictable delivery windows, and a voucher loop that rewards planning—not one-off deals.

The Maintenance Window Playbook

Use the campaign period—whether 48–72 hours, 3–5 days, or a weekend—to compress routine maintenance and urgent fixes into one coordinated window.

- Phase 1 — Map the fleet: list active units, serial numbers, and open issues; flag machines with downtime risk.

- Phase 2 — Verify part numbers: cross-check codes with manuals/records; attach photos where useful.

- Phase 3 — Build two carts: a “core” cart (filters, oils, seals) and a “task” cart (immediate repairs) to capture vouchers.

- Phase 4 — Lock delivery windows: align ETAs with crew shifts; book same-day where available for critical lines.

- Phase 5 — One-pass execution: complete replacements in a single pass to avoid reopening systems.

- Phase 6 — Apply voucher credits: use returned credits on top-ups or follow-ups within the window.

- Phase 7 — Document and reset: update part logs, photo records, and the next 30-day plan.

See live offers and schedule your window

Check voucher rules, first-order benefits, and delivery coverage across Thailand.

Thailand Spare Parts Mega Sale — Official Page

Why this works during the campaign

- Verified parts: SANY genuine listings are checked for part codes and compatible models before going live.

- Voucher loop: credits on qualifying orders lower average annual cost when applied to follow-ups.

- First-order benefit: a low-friction way to trial the platform on smaller replenishment lines.

- Predictable ETAs: local fulfillment, including same-day options in select areas, to plan shifts around arrivals.

- Traceable paperwork: clear status (new/refurb) and retained inspection notes for smoother after-sales.

Ordering tactics that protect schedules

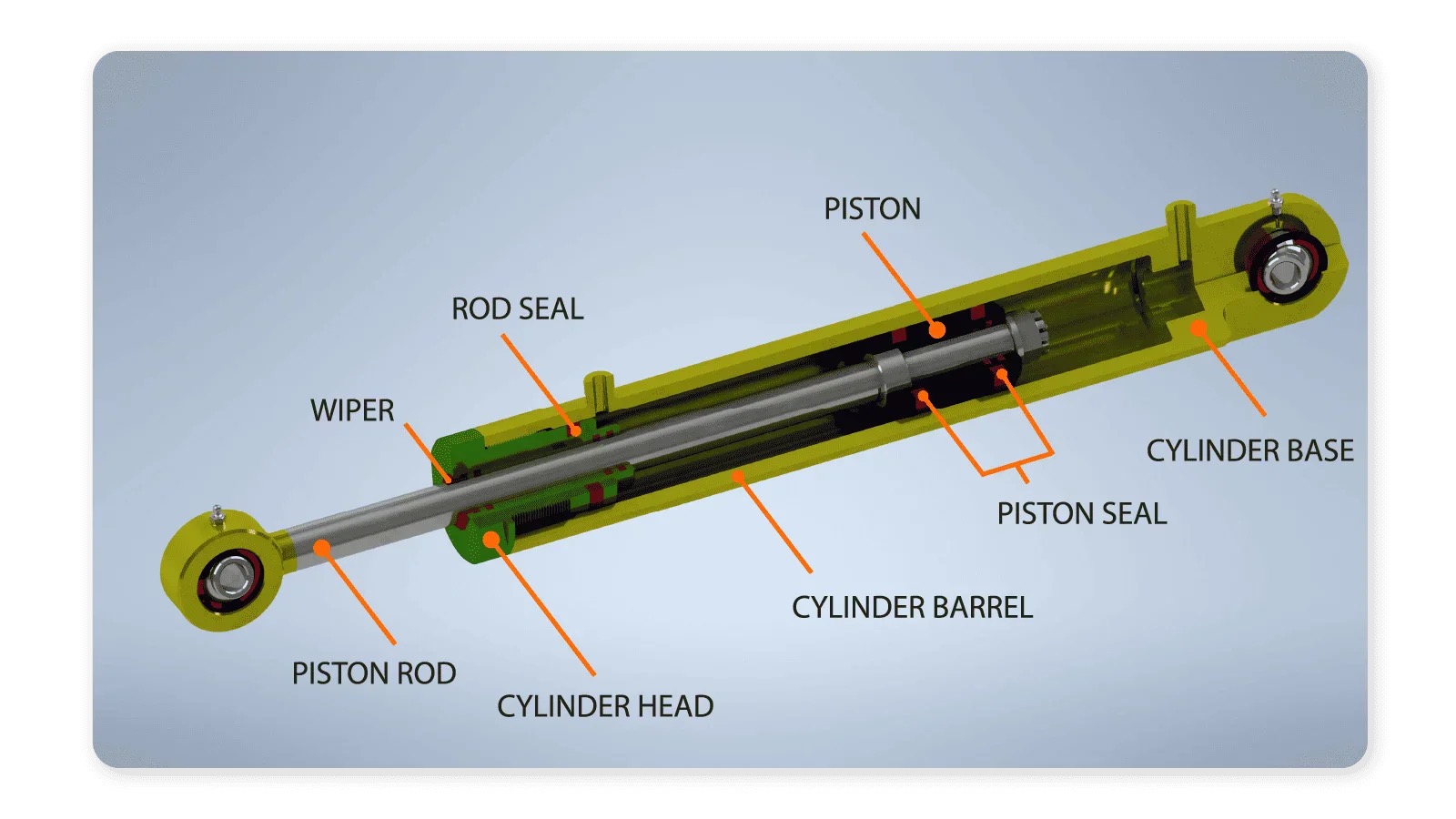

- Bundle adjacent items: if you open a hydraulic circuit, pair seals and filters with the primary fix.

- Stagger by risk: put high-risk parts in the first cart; defer non-critical lines to the voucher-backed follow-up.

- Group by location: ship to where crews will be—yard vs. site—so parts and people meet on time.

High-demand SANY categories

- Hydraulic: pumps, hoses, seals, valves

- Undercarriage: rollers, idlers, sprockets, track shoes

- Powertrain: final drives, travel motors, torque converters

- Wear parts: bucket teeth, cutting edges, ripper shanks

- Electrical & controls: sensors, panels, joysticks

- Cooling & filtration: radiators, coolers, air & hydraulic filters

In practice: pressure to predictability

A Pathum Thani contractor split work into a “core” order and a “task” order within one window. Vouchers from the core order offset the follow-up; a critical seal kit shipped same-day. By the end, downtime hours fell and next-month plans were locked with updated part logs.

Next steps

Browse SANY genuine parts and request a quote: SANY Genuine Spare Parts on MechLink

Plan your maintenance window around the campaign: Thailand Spare Parts Mega Sale (Vouchers, First-Order Benefits, Same-Day Options)

What if a short, well-planned window could reset your fleet’s reliability—and your parts budget? On many Thai job sites, downtime is a chain of small delays: a late seal kit, a missing document, a second stoppage. This limited-time campaign is built to break that cycle with verified SANY genuine parts, predictable delivery windows, and a voucher loop that rewards planning—not one-off deals.

What if a short, well-planned window could reset your fleet’s reliability—and your parts budget? On many Thai job sites, downtime is a chain of small delays: a late seal kit, a missing document, a second stoppage. This limited-time campaign is built to break that cycle with verified SANY genuine parts, predictable delivery windows, and a voucher loop that rewards planning—not one-off deals.