— December 8, 2025

When it comes to construction, tires have an outsized impact on the performance of your heavy equipment. Tires come in a wide variety of sizes and types, and choosing the best tires for your application can help your equipment operate more efficiently, saving you time and money.

Unfortunately, it isn’t always obvious which tires are best suited to your equipment and the task at hand. If you choose tires that aren’t well-suited to your application, you may run into traction issues and the tires may wear down quickly, costing you more money in the long run.

Here, we dive into the basics of tire design and tread patterns for construction equipment. By understanding the types of tires and tread patterns available, you can choose the best tires for your equipment and application.

If you’ve been shopping for heavy equipment tires, then you may have heard sales reps talk about “L-3”, “L-5”, or “E-3” tires. Each of these codes refers to a specific kind of tire with a specific type of tread.

The Tire and Rim Association (TRA) maintains a tire classification system that is used to classify tires according to their type and tread. The abbreviation system consists of two components – a letter and a number.

The letter portion of a tire’s TRA code represents the type of tire. Tires are assigned one of four letters, according to their type:

Meanwhile, the number portion of the tire’s TRA code refers to the tread and tread depth of the tire. There are 4 classifications of tread:

So, for example, an L-3 tire is a tire made for loaders and dozers, with a normal tread of regular depth. An L-5 tire, on the other hand, is a tire made for loaders and dozers, with a very deep tread.

Sometimes, the TRA code may also be followed by another letter, which provides additional information about the tire’s tread pattern. If you see a TRA code that ends with a letter, here is what that letter means:

TRA codes are widely used and recognized throughout the construction and heavy equipment industries, making it much easier to order replacement tires. If you aren’t sure of the TRA code of your machine’s tires, check a tire’s sidewall. The TRA code is usually printed there, alongside other information about the tire.

In addition to a tire’s classification and tread depth, it’s also important to consider its tread pattern. While tread depth describes the depth of a tire’s tread, a tire’s tread pattern refers to the shape and orientation of its tread blocks.

In general, there are a few features that will determine how suitable a particular tread pattern is for your application:

Heavy equipment tire manufacturers typically have several dozen or more tread patterns to choose from. Each manufacturer might have a different way of naming and classifying these patterns, so it’s best to work with a licensed dealer to discover the best tread pattern for your application.

Choosing the best type of heavy equipment tire for your needs involves considering various factors, including tire types and tread patterns. Here are some steps to take when trying to choose the best tires for your application:

Once you’ve found the right tires for your heavy equipment, it’s important to take the necessary steps to maintain them. Like other components, your machine’s tires will last longer and function more efficiently when they are looked after as part of a comprehensive preventive maintenance plan.

Tires should be sprayed down and cleaned at the end of each shift. This will prevent mud and other debris from caking on the tires, preventing unnecessary wear. It’s also important to maintain your tires’ inflation level. Tires that are over- or under-inflated may wear down more quickly, increasing operating costs.

For additional tire maintenance tips, check out our guide on tire maintenance best practices.

Type and tread pattern are critical aspects to consider when purchasing a new set of tires for your heavy equipment. Choosing the right tires for your application will help them last longer, resulting in less hassle and greater cost savings for your team.

Understanding the different types of bearings used in construction machinery

December 8, 2025

Demolition essentials: a guide to selecting the right heavy equipment

December 5, 2025

How to reduce construction noise pollution with proper maintenance

December 5, 2025

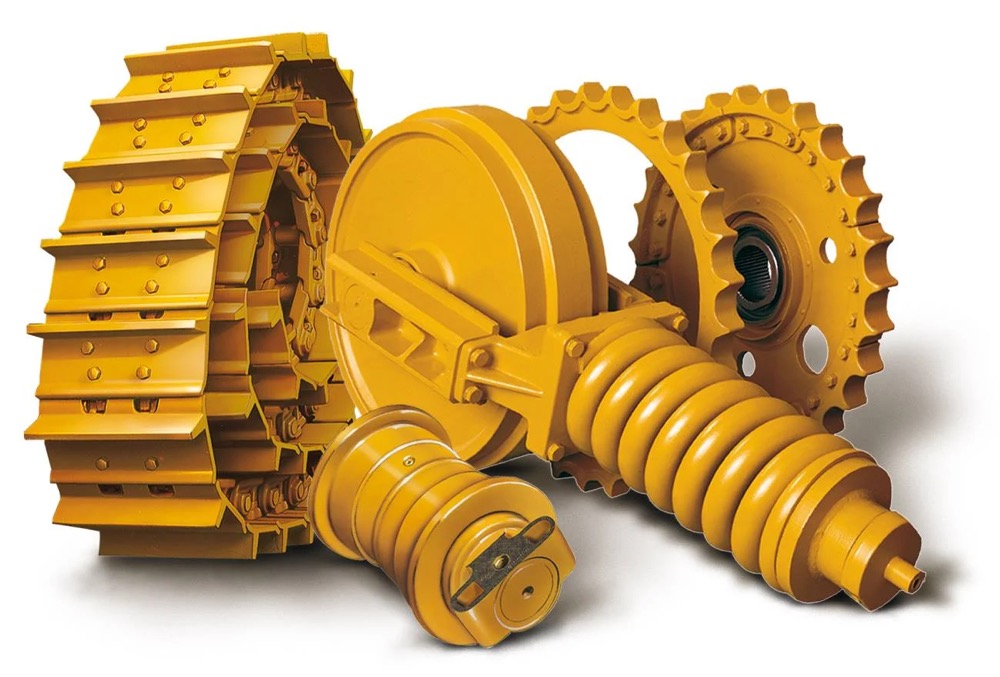

How undercarriage rollers dictate the performance of your equipment

December 4, 2025