— November 12, 2025

Aerial lifts are an essential type of heavy equipment capable of hoisting workers high into the air to reach hard-to-access work areas. While they’re most commonly used in construction, aerial lifts are versatile machines with applications in numerous industries, from manufacturing to film production.

Some popular types of aerial lifts include boom lifts, cherry pickers and scissor lifts. While each type of aerial lift has a different design, they share the common purpose of providing workers with a stable work platform at great heights.

Like all heavy equipment, however, aerial lifts need to be properly maintained in order to operate efficiently and safely.

Because falls continue to be the most common cause of fatal construction accidents, it’s of paramount importance that operators and fleet managers understand how to properly maintain aerial lifts.

In this guide, we’ll go over the basics of aerial lift maintenance, including preventive maintenance guidelines and safety best practices. Through properly maintaining your aerial lift, you can improve your team’s efficiency and keep them safe.

As aerial lifts are commonly used for indoor applications, many models are battery-powered. Properly caring for the lift’s battery represents one of the most important preventive maintenance objectives.

Generally, battery-powered aerial lifts feature deep cycle batteries. A deep cycle battery is a particular type of battery designed to supply consistent power over a sustained period of time.

In most cases, aerial lift batteries are also flooded, meaning the battery’s cells are submerged in an electrolyte solution which must be regularly topped off with distilled water.

To get the most out of your aerial lift’s battery, you should implement a few simple practices:

While the above practices will help you get the most out of your battery, older batteries will eventually need to be replaced.

If your aerial lift’s battery no longer holds a charge, or if charge times become excessively long, then you may need to replace it.

In addition to your lift’s battery, other systems need to be regularly maintained as well. Here are some key maintenance areas that should form the basis of your preventive maintenance program:

Because they are used to lift personnel into the air, inspecting aerial lifts prior to each use is a critical safety requirement. By inspecting the lift and ensuring its safety features are operational, you can help prevent accidents.

In fact, aerial lift inspections are so important that OSHA provides direct guidance for conducting these inspections. According to their guidance, the following areas should be inspected at the start of each shift:

When it comes to ensuring the safe use of aerial lifts, safety practices can be broken down into operator safety and machine safety. Operator safety involves properly training operators to perform safety checks, while machine safety involves maintaining the physical components of your aerial lift.

Before operating an aerial lift, all operators should receive adequate training. Some important aspects of operator safety include work zone inspections, personal protective equipment (PPE), and work platform awareness.

Operators should be trained to inspect their work zone prior to operating an aerial lift. During work zone inspections, operators should look out for and address potential hazards such as drop-offs, holes, unstable surfaces, bumps, debris and other obstructions, overhead obstacles (especially power lines), inclement weather and the presence of other personnel in the work zone.

Operators should use personal protective equipment at all times. This includes basic gear - hard hats, gloves and safety vests. Where applicable and recommended or required by law, operators should also use harnesses or leashes to secure themselves to the work platform.

Importantly, operators should exercise a very high level of caution while working atop the elevated work platform of an aerial lift.

Operators should be well-trained to remain inside the work platform at all times, and should never attempt to climb over the guardrails or breach the work platform in any way. Operators should only enter and exit the work platform while the lift is in a lowered position and using the dedicated safety gate.

Operators should be well-trained to inspect their aerial lift and ensure it is safe to operate before using it. When maintenance issues that adversely impact the machine’s safety are discovered, operators should report those issues and address them before operating the equipment.

In addition to improving job safety for you and your operators, taking proper safety precautions will help your team remain in compliance with legal requirements established by organizations like OSHA and ANSI.

For example, ANSI standards require a thorough inspection of aerial lifts every three months or 150 hours. Training your team to meet these requirements, as well as others, will help keep your team compliant and reduce your liability in the case of an unforeseeable accident.

While aerial lifts are incredibly useful for a wide range of applications, they must be properly maintained in order to keep your team safe from accidents.

MechLink is here to help you rent, purchase and maintain aerial lifts for your team. Our online shop carries OEM and aftermarket parts for various aerial lifts, making it easier than ever to keep your lift in good working condition. Can’t find the part you need? Contact one of our parts experts for personalized assistance.

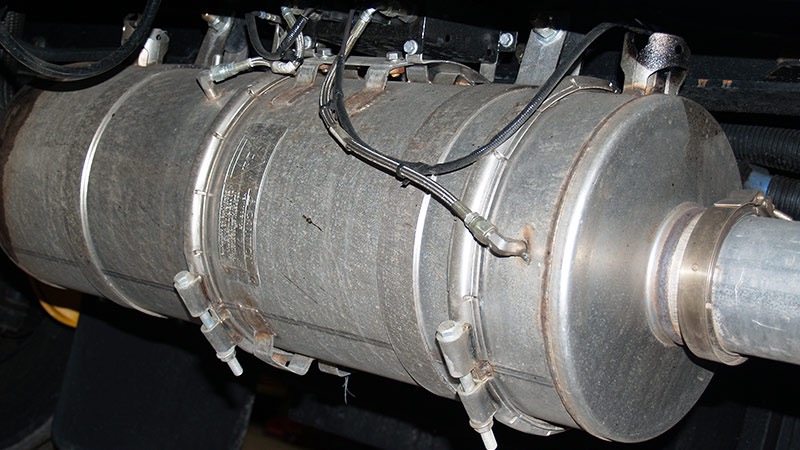

What is a diesel particulate filter and how do you maintain it?

December 26, 2025

Compact track loader attachments: a guide to unlock your machine’s full capabilities

December 26, 2025

Heavy equipment tire wear and what it can reveal about your machine

December 25, 2025

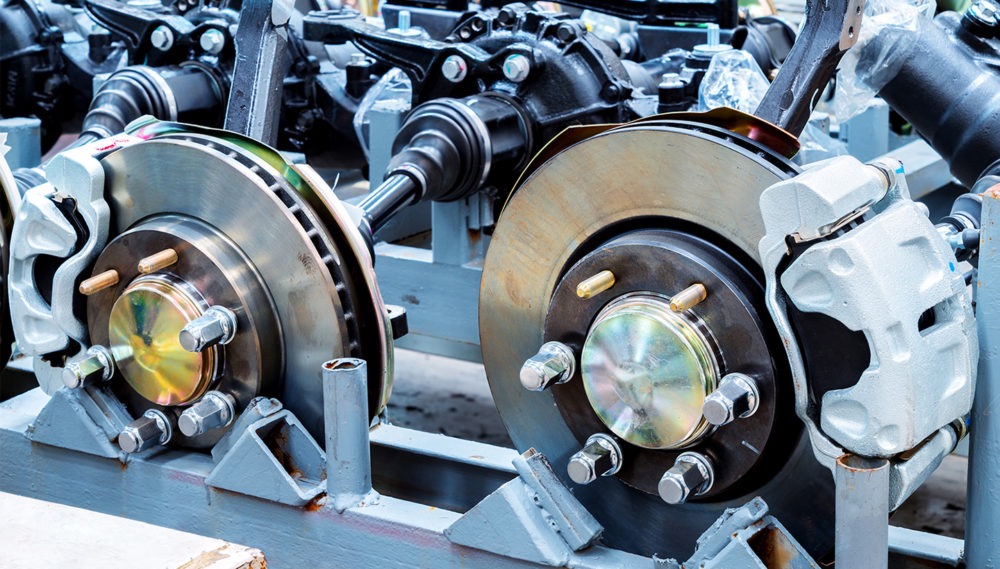

Heavy equipment brake systems: why regular inspections are crucial

December 25, 2025