Selecting a used aerial work platform (AWP) is a significant investment for any business involved in construction, facility management, logistics, or industrial maintenance. In China’s rapidly evolving industrial landscape, the demand for reliable and cost-effective AWPs continues to grow, especially as companies seek sustainable solutions that balance safety, efficiency, and budget. This guide provides a detailed, step-by-step approach to help you make an informed decision when purchasing a used AWP, ensuring your investment delivers long-term value and operational safety.

1. Clarify Your Operational Needs

Before considering any specific model or brand, it’s crucial to clearly define your operational requirements. Start by analyzing the following aspects:

- Maximum Working Height: Determine the highest point your workers need to reach. Always choose a platform with a slightly higher reach than your maximum requirement to allow for flexibility and safety.

- Load Capacity: Calculate the total weight the platform must support, including workers, tools, and materials. Overloading is a leading cause of accidents, so never compromise on this factor.

- Type of Tasks: Are you primarily performing maintenance, installation, or construction? Different tasks may require different platform types or features.

- Frequency of Use: Will the AWP be used daily or only occasionally? Frequent use justifies investing in higher-end models with robust components.

By thoroughly understanding your needs, you can narrow down your choices and avoid overpaying for unnecessary features or, worse, selecting equipment that falls short.

2. Choose the Right Type of Aerial Work Platform

There are several main categories of AWPs, each suited to specific applications:

- Scissor Lifts: Best for vertical lifting in indoor environments such as warehouses and factories. They offer high stability and generous platform space, making them ideal for tasks requiring multiple workers or bulky tools.

- Articulating Boom Lifts: These provide flexible reach, allowing operators to navigate around obstacles. They are perfect for maintenance in complex environments like industrial plants or shopping malls.

- Telescopic Boom Lifts: Designed for maximum horizontal outreach, these are suited for outdoor construction sites where you need to access hard-to-reach areas.

- Personnel Lifts: Compact and lightweight, they are ideal for quick, solo tasks in tight spaces.

Selecting the right type directly impacts safety and efficiency. For example, using a scissor lift outdoors on uneven ground is risky, while a boom lift may be overkill for simple indoor repairs.

3. Assess Safety Features and Compliance

Safety should always be the top priority when purchasing a used AWP. When evaluating a used AWP, check for:

- Guardrails and Toe Boards: These prevent falls and are essential for worker protection.

- Emergency Lowering Systems: In the event of power failure, these systems allow safe descent.

- Tilt and Overload Sensors: Modern AWPs are equipped with alarms and automatic shutdown features if unsafe conditions are detected.

- Non-slip Platforms: Ensure the platform surface is designed to prevent slips, especially in wet or oily environments.

- Up-to-date Inspection Records: Request maintenance logs and inspection certificates to verify the machine’s condition and compliance with safety regulations.

Never compromise on safety features, even if it means paying a little more. A safe work environment protects your team and reduces the risk of costly accidents or legal issues.

4. Evaluate Equipment Condition and Maintenance History

When buying a used aerial work platform, a thorough inspection is essential. Pay close attention to:

- Structural Integrity: Check for cracks, rust, or signs of previous repairs on the chassis, boom, and platform.

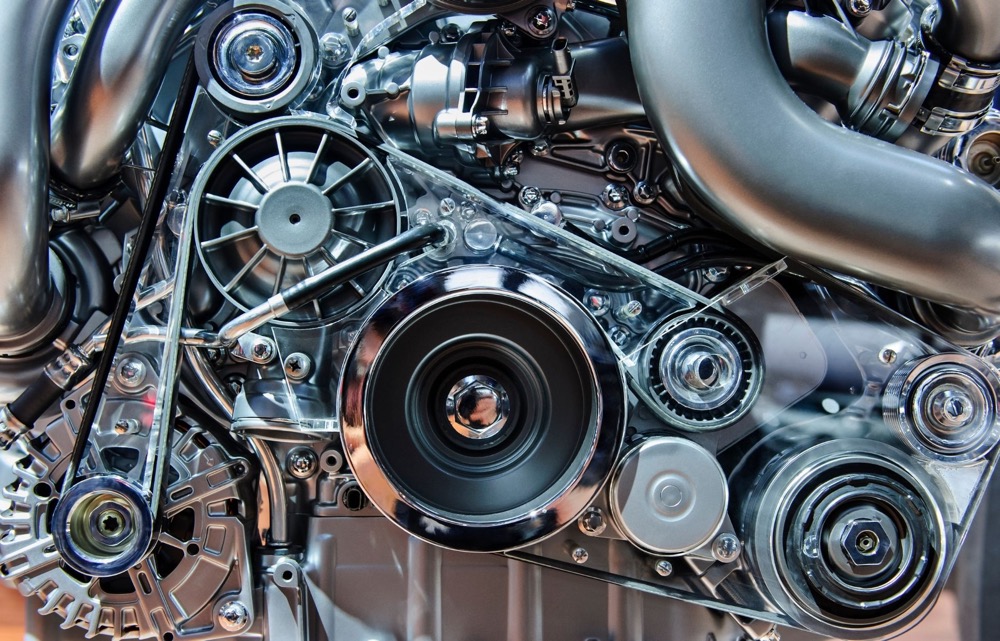

- Hydraulic System: Inspect for leaks, smooth operation, and consistent pressure.

- Electrical Components: Test all controls, emergency stops, and alarms. Faulty wiring can lead to dangerous malfunctions.

- Battery or Engine Health: For electric models, assess battery age and runtime. For diesel or gasoline units, review engine maintenance records.

- Tires and Brakes: Worn tires or malfunctioning brakes are safety hazards, especially on uneven or sloped surfaces.

A reputable supplier will provide detailed refurbishment reports and allow you to test the equipment before purchase. If possible, have a qualified technician accompany you for the inspection.

5. Consider Environmental and Site Factors

The environment where the AWP will be used significantly influences your choice:

- Indoor vs. Outdoor: Electric AWPs are ideal for indoor use due to zero emissions and quieter operation. Outdoor environments often require diesel-powered units with robust tires and weather-resistant features.

- Surface Conditions: For rough or uneven terrain, choose models with all-terrain tires and automatic leveling systems.

- Space Constraints: Measure doorways, aisles, and turning radii at your site to ensure the equipment fits and maneuvers easily.

By matching your AWP to the work environment, you enhance both productivity and safety.

6. Analyze Cost, Value, and Supplier Reputation

While budget is always a concern, the lowest price does not always equal the best value. Consider:

- Total Cost of Ownership: Factor in maintenance, spare parts, and potential downtime, not just the purchase price.

- Warranty and After-sales Support: Choose suppliers who offer warranties and reliable after-sales service. This reduces long-term risk and ensures you’re not left stranded if issues arise.

- Supplier Reputation: Work with established suppliers, known for quality refurbishment, transparent processes, and comprehensive support.

A trusted supplier will help you avoid hidden costs and provide peace of mind throughout the equipment’s lifecycle.

7. Prioritize Operator Training and Ongoing Safety

Even the best equipment requires skilled operators. Make sure your team receives:

- Comprehensive Training: Covering safe operation, emergency procedures, and routine maintenance checks.

- Regular Safety Refreshers: Ongoing education ensures best practices are followed and new team members are up to speed.

- Clear Safety Protocols: Post operating instructions and emergency contacts near the work area.

Investing in operator training not only prevents accidents but also extends the lifespan of your equipment.

Conclusion: Why MechLink is Your Trusted Partner for Used AWPs

Choosing a safe and efficient used aerial work platform is a multi-step process that demands careful consideration of your operational needs, equipment condition, safety features, and supplier reliability. As a leading China aerial work manufacturer, MechLink stands out by offering:

- Strict Adherence to National Safety Standards: Every platform is refurbished and tested to meet or exceed GB/T safety standards.

- Transparent Maintenance Records: We provide detailed inspection and service histories for every unit.

- Comprehensive After-sales Support: Our team offers training, technical support, and quick-response maintenance, ensuring your equipment stays in peak condition.

- Custom Solutions: Whether you need a refurbished scissor lift for indoor logistics or a robust boom lift for construction, MechLink used AWPs tailors solutions to your business.

By partnering with MechLink, you gain access to a wide range of reliable, cost-effective AWPs backed by industry expertise and a commitment to your safety and success. For more information or to explore our current inventory, visit our official website and discover how we can help elevate your business to new heights.