— December 2, 2025

Engines are the heart of all modern heavy equipment. By combusting fuel, engines produce tremendous power, allowing machines to perform incredible feats of strength with ease.

During the combustion process, a machine’s engine produces a large amount of heat. If not managed properly, the excess heat generated in the engine may cause it to perform inefficiently, leading to a host of malfunctions and causing the engine to break down.

Cooling systems are designed to help maintain the engine at a constant temperature, preventing the engine from becoming too hot. Most heavy equipment uses a liquid-based cooling system, which cools the engine by circulating coolant through the engine block.

As coolant absorbs heat in the engine block, it is cycled out of the engine and into the radiator. In the radiator, coolant is forced through an array of narrow, gilled tubes, which efficiently dissipates excess heat from the coolant.

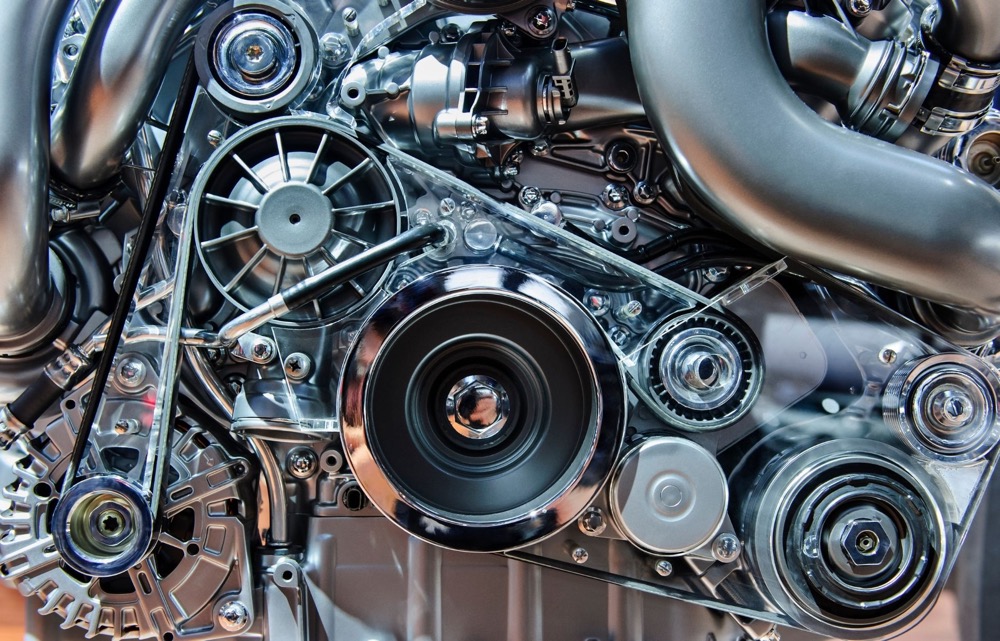

To facilitate the exchange of coolant between the engine and radiator, a host of components like fans, fan drives, thermostats and valves must work in tandem. Collectively, these components help maintain the engine at the ideal temperature, preventing it from running too cool or too hot.

In this guide, we’ll cover the ins and outs of maintaining heavy equipment cooling systems. By keeping your machine’s cooling system in good operating condition, you can help extend the life of its engine and avoid costly repairs.

When your machine’s cooling system malfunctions, engine troubles lie just around the corner. Without a properly functioning cooling system, the engine is bound to overheat, leading to a host of performance issues.

By recognizing the signs of a failing cooling system early on, you can avoid costly breakdowns and damage to your machine’s engine. Here are some warning signs to look out for.

If your machine is exhibiting any of the issues above, stop operation and have it serviced. Continuing to operate heavy equipment with a malfunctioning or broken cooling system can have serious and potentially catastrophic consequences for the equipment itself and its engine.

When it comes to maintaining your machine’s cooling system, a strategy of preventive maintenance is preferred to one of reactive maintenance. By maintaining your machine’s cooling system according to a well-defined schedule, you can make sure maintenance tasks don’t slip through the cracks.

Here are some important maintenance tasks that should form the basis of your cooling system maintenance plan.

An essential task of cooling system maintenance is maintaining proper coolant levels. Low coolant levels can result in a drop in performance and engine overheating. Older cooling systems typically require a mixture of distilled water and antifreeze, while newer systems require a specific liquid coolant.

To find the type of coolant required by your machine’s cooling system, consult the service manual. Check the coolant levels often, and replenish the coolant as needed.

As the radiator releases heat into the surrounding environment, the air around the radiator becomes hot. The radiator fan has the important task of keeping fresh air circulating around the radiator, cooling it down and facilitating the dissipation of heat around the radiator.

If the fan blades become stuck, bent, chipped or damaged, the radiator will have a diminished ability to cool down the engine, leading to performance issues. To keep the radiator fan working properly, inspect it once per week, making sure to address any issues immediately.

In addition to removing excess heat from the cooling system, coolant also plays a role in preventing corrosion inside the radiator and the cooling jacket of the engine block. Over time, coolant becomes less effective at both of these tasks, making your cooling system less effective and more prone to corrosion.

To prevent avoidable damage to your machine’s cooling system, it’s important to replace the coolant regularly. For best results, consult your machine’s service manual and replace the coolant according to the intervals set by the manufacturer.

Due to their high surface area, radiators are incredibly efficient at dissipating heat to the outside environment. However, if the radiator becomes covered in dust, mud or other debris, its ability to transfer heat to the surrounding air may become greatly hampered.

Begin each shift by inspecting the radiator and clearing away any mud or debris that may hinder its performance.

One common cause for coolant leaks is worn seals, hoses and fittings. As hoses, seals and fittings become corroded, cracked or worn, they may lose their ability to keep the cooling system sealed off.

To prevent coolant leaks, check the system’s hoses, seals and fittings regularly, keeping them clear of dirt and debris. Pay special attention to cracked hoses and corroded fittings, and replace them as soon as possible.

While maintaining proper coolant levels is critical to the performance of your cooling system, it isn’t always enough. Coolant analysis is a type of test that can reveal impurities in your coolant, problems with its admixture or other indicators of a failing cooling system.

To get the full benefits of coolant analysis, perform this test at the beginning of each summer and winter.

Cooling systems are intricate, yet vital parts of all modern heavy equipment. Without efficient cooling systems, the capabilities of our machines would be greatly reduced. Keeping your machine’s cooling system in good working order will help its engine operate smoothly and efficiently.

The MechLink Shop is a useful tool for operators and fleet managers looking to purchase OEM and aftermarket parts for heavy-duty engine cooling systems–such as radiator hoses, coolant filters, fans, pumps and more. Can’t find the part you’re looking for? Reach out to our parts experts to place a custom order.

Final drive maintenance tips: preventing issues before it’s too late

December 2, 2025

The cost of engine idling: how letting your equipment idle can worsen your fleet

December 1, 2025

Sany sy35u filter change

December 1, 2025

Excavator buckets: how to select the best type of bucket for your job

November 28, 2025