— October 24, 2025

When a machine in your construction fleet breaks down, your entire project can go off the rails. Breakdowns lead to downtime, delaying your project’s completion date and causing costs to balloon. Preventive maintenance can prevent unexpected breakdowns, leading to improved efficiency and less downtime.

Preventive maintenance is a strategy for your heavy equipment fleet which aims to address maintenance issues before they become problematic. Preventive maintenance involves carrying out maintenance tasks according to an established maintenance schedule, improving machine performance and minimizing downtime.

Heavy equipment machinery requires routine maintenance in order to operate at peak efficiency. Tires need to be rotated and retreaded, oil needs to be changed, bucket teeth need replacing and pivot points need greasing.

As your fleet expands, the number of maintenance tasks required to keep your heavy equipment in proper working condition grows larger. When managing a fleet of a dozen or more machines, these tasks can become overwhelming and you may unintentionally neglect crucial maintenance tasks.

Preventive maintenance is a strategy for systematizing your fleet’s maintenance tasks so no machine in your fleet becomes neglected. In its most basic form, a preventive maintenance strategy involves the implementation of a maintenance schedule for your fleet.

A preventive maintenance schedule defines which maintenance tasks need to be performed, who is responsible for carrying them out and when they need to be carried out. The outcome of each maintenance task is logged and any issues discovered during maintenance are addressed immediately.

Reactive maintenance, sometimes called breakdown maintenance, is a strategy that involves repairing machines only once they have broken down. Under this style of maintenance, no preventive measures are taken to avoid mechanical failures before they occur. You may have come across fleet managers or operators who follow a reactive maintenance strategy. The strategy is summed up by the colloquial phrase, “If it ain’t broke, don’t fix it!”

While a reactive maintenance strategy may seem appealing at first, it is more costly in the long run. Not only does this maintenance style lead to more frequent breakdowns, but breakdowns will tend to be more severe when they do occur.

A properly designed preventive maintenance strategy reduces operating costs and helps you get the most out of your heavy equipment fleet. Along with improved reliability, a well-executed preventive maintenance strategy enhances operator safety and improves the efficiency of your workforce.

Preventive maintenance is one of the best ways to lower maintenance costs. A good preventive maintenance strategy involves regularly scheduled inspections to ensure that your machine’s mechanical components, hydraulics and electrical system are working properly.

Component failures frequently set off chain reactions and the failure of a single component can lead to system-wide failures.

By inspecting your machines regularly and thoroughly, you can prevent costly system-wide failures and keep your machines out of the service yard.

Heavy equipment needs to be maintained correctly in order to operate efficiently. Every machine comes with a list of recommended maintenance tasks, which you can find in the machine’s operating manual.

When these maintenance tasks are neglected, the machine’s performance suffers, leading to a dip in your fleet’s productivity.

For example, a backhoe used for digging needs to have its bucket teeth replaced regularly. If you allow the teeth to run down to the shanks, the machine’s digging power will be greatly reduced and it will take your operators more time to perform the same task.

Preventive maintenance ensures your machines can perform the tasks they were designed for and improves the productivity of your operators.

Downtime is one of the most costly side effects of poor fleet maintenance. When your heavy equipment breaks down, not only do you incur expensive service fees, but your operators can’t do their job.

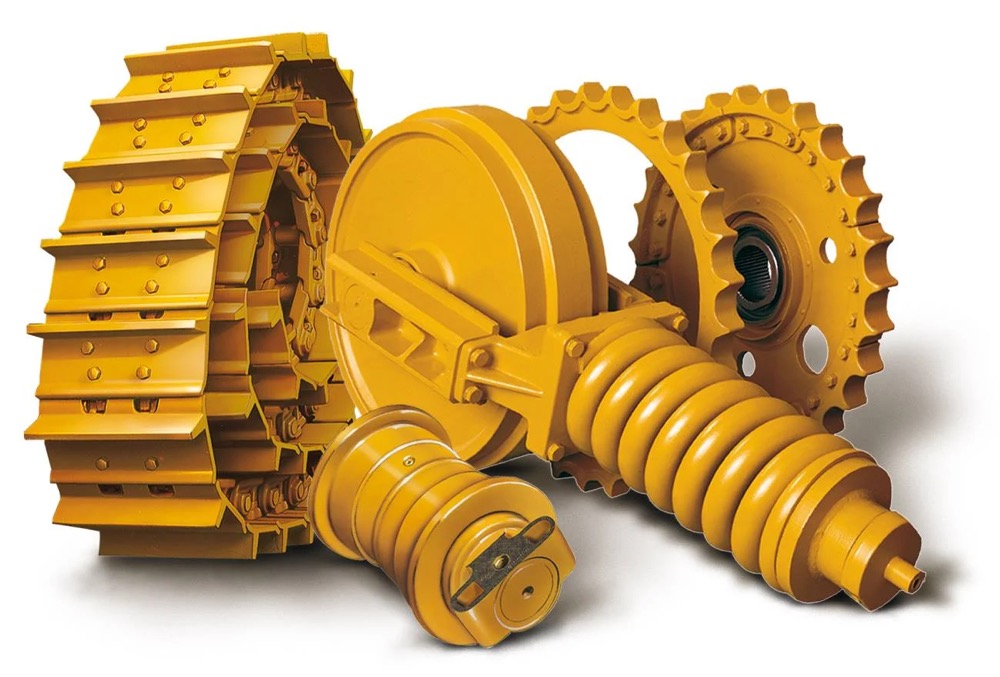

Preventive maintenance minimizes downtime by anticipating component failures before they happen. Components, which are prone to gradual failure, can be monitored and regularly inspected. When a component nears the end of its lifespan, it can be replaced before breaking down.

Replacing wearing parts as part of a comprehensive preventive maintenance program is the best way to prevent unexpected downtime.

Preventive maintenance doesn’t just make your machines run better, it makes them safer to operate, too. A good preventive maintenance program will require your operators to regularly inspect their machine’s safety devices.

Safety components like lights, horns, locks, alarms, pedals and fire extinguishers all need to be monitored and replaced, if needed.

By monitoring and maintaining your machine’s safety equipment, you can avoid unnecessary accidents. When accidents do occur, you will be able to show that you were not negligent. You took the necessary steps to inspect and maintain the safety features of equipment in your fleet.

When crafting a preventive maintenance plan, it’s difficult to know where to begin. Different machines have various maintenance requirements, and it isn’t easy to create a plan that addresses the needs of your entire fleet in a unified strategy.

Developing an effective and consistent preventive maintenance strategy is the best way to reduce maintenance-related operating costs and keep your fleet in good condition for years to come. When it comes time to replace worn or damaged components, shop for heavy equipment parts here. If you’re unsure about the parts you need or can’t find them, reach out to one of our parts experts for help.

Demolition essentials: a guide to selecting the right heavy equipment

December 5, 2025

How to reduce construction noise pollution with proper maintenance

December 5, 2025

How undercarriage rollers dictate the performance of your equipment

December 4, 2025

The critical role of pins and bushings in heavy equipment (and how to prolong their lifespan)

December 4, 2025