— January 7, 2026

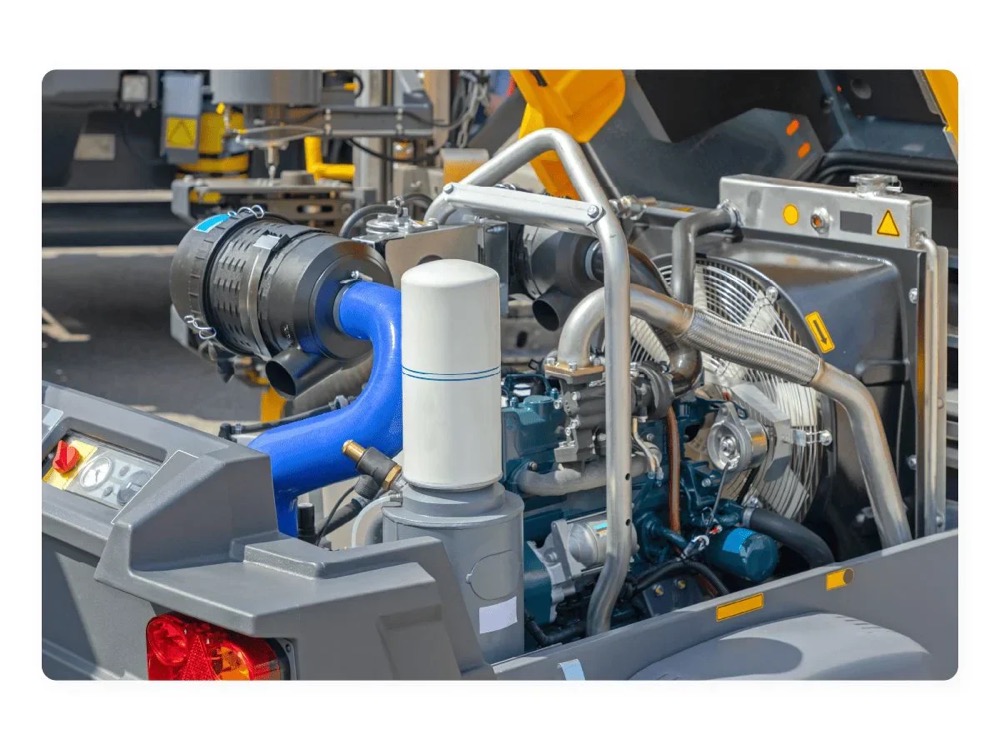

Excavators, front loaders, dozers and other popular types of heavy equipment rely on hydraulic power to perform demanding tasks like digging, lifting and pushing. The hydraulic pump serves the key function of moving hydraulic fluid in and out of the hydraulic cylinders, creating mechanical forces that power the machine.

Through the process of fluid displacement, hydraulic pumps allow machinery to handle heavy loads, offering a level of power and efficiency that’s unmatched by electric or pneumatic systems.

Given its importance, the failure of a hydraulic pump can lead to significant consequences, affecting not just the functionality of the machine but also leading to downtime, increased repair costs and potentially hazardous situations on the job site.

Understanding the causes and symptoms of hydraulic pump failure is crucial for operators, service techs and fleet managers to prevent or mitigate these issues. In this article, we’ll get into the intricacies of hydraulic pumps used in construction equipment. Understanding common causes of failure and implementing certain maintenance practices will help you get the most out of your machine’s hydraulic system.

Hydraulic systems work by using power from the machine’s engine to drive a hydraulic pump. The hydraulic pump draws hydraulic fluid out of the reservoir, pressurizes it and then delivers it to the machine’s hydraulic cylinders through a system of hoses.

In hydraulic cylinders, an inflow of pressurized hydraulic fluid causes the cylinder’s rod and piston to move and expand, generating mechanical force. This mechanical force powers the movements of a machine’s bucket, arm and attachments.

The efficiency and effectiveness of a hydraulic system are heavily dependent on the pump's ability to provide a steady and controlled flow of pressurized fluid. In most construction equipment, piston pumps are used due to their reliability and efficiency.

Before your machine’s hydraulic pump fails, it may exhibit some warning signs. Here are some of the most common symptoms of hydraulic pump failure you should watch out for.

This symptom could be a sign that the hydraulic pump is not operating at its optimal capacity, leading to slower work cycles and reduced overall efficiency. If you’ve noticed that your machine struggles to lift heavy loads or seems sluggish, the hydraulic pump may be failing.

A loss of power can significantly disrupt operations, as it affects the equipment's ability to perform its intended tasks. This symptom can range from a slow decline to an abrupt failure, indicating serious internal issues within the pump that require immediate attention.

When hydraulic equipment operates more slowly than usual, it may suggest that the hydraulic system is not receiving enough power from the pump. This inefficiency can delay projects and increase operational costs.

This indicates a lack of smooth flow in the hydraulic fluid, possibly due to air entrapment or fluctuations in pump pressure. Such inconsistency can lead to precision tasks being performed poorly, raising safety concerns on the job site.

Noise often precedes other more tangible symptoms of failure. It can indicate various issues, from cavitation to mechanical wear, signaling that the pump requires inspection.

These sounds are more serious than general noise and often suggest severe internal wear or failure. Such conditions usually demand immediate pump repair or replacement to prevent further damage.

Problems with the hydraulic fluid, including contamination and improper levels, can lead to a host of issues, from decreased performance to complete system failure. Regular fluid checks and maintenance are crucial.

Hydraulic leaks not only lead to fluid loss but also reduce the system's pressure and efficiency. They can also pose environmental and safety risks, making prompt detection and repair essential.

Visible damage to the pump, such as wear and tear or cracks, can compromise the system's integrity and lead to leaks or failure. Regular inspections can help identify and address these issues early.

Overheating can degrade hydraulic fluid and damage system components, indicating that the pump is operating beyond its limits or that there is insufficient cooling.

If the pump is working inefficiently, the equipment may require more power to perform the same tasks, leading to increased fuel consumption and operational costs.

The most common causes of hydraulic pump failure include:

Regular maintenance practices are crucial for maintaining the health of your machine’s hydraulic pump. These practices include checking hydraulic fluid levels, inspecting hoses and connections for leaks and ensuring the hydraulic fluid is clean and free of contaminants.

Maintenance should occur at intervals recommended by your machine’s manufacturer, as given in its service manual, typically after every 250 to 500 hours of operation.

Addressing common wear and tear involves routinely inspecting and replacing worn-out parts, such as seals and filters, to maintain system integrity and efficiency.

Best practices for operating machinery to prevent hydraulic problems include following operational guidelines, avoiding overloading and using the correct attachments.

Hydraulic pumps are critical to the operation and efficiency of heavy equipment. The costs associated with replacing a standard hydraulic pump can be significant, not just in terms of the part itself but also due to downtime and lost productivity.

Fortunately, the MechLink Shop offers a convenient solution by carrying both OEM and aftermarket hydraulic components for a diverse range of machine types. Our online shop helps operators and fleet managers find the right parts to maintain or repair their equipment promptly. Don’t see exactly what you need? Reach out to our parts experts and get personalized assistance.

What is wet stacking and how do you prevent it?

January 8, 2026

The most common heavy duty air compressor problems and how to prevent them

January 8, 2026

A look at takeuchi equipment: your options and their advantages

January 7, 2026

The different types of heavy duty oil filters

January 6, 2026