— August 14, 2025

Choosing the right excavator machine for mining depends on factors like load capacity, hydraulic system, durability, and site conditions. Top models from brands like CAT excavator, Tata Hitachi excavator, SANY excavator, and Volvo excavator offer excellent performance for heavy-duty operations. Considering the excavator price in India and support services are essential for long-term efficiency.

The mining industry has been evolving since its inception. In the mining world, efficiency and productivity are the keys to success. With the advent of advanced technology, the mining industry has seen substantial growth in recent times. However, with the availability of so much equipment and different types of excavators offering almost similar functions, identifying the correct model of equipment for the project is very necessary; otherwise, the mining activity will not reach its maximum potential.

Choosing the right model for the right tasks is necessary to get optimal performance and results. Mining excavators are large machinery used for large-scale excavation, material handling, and digging. These excavators are equipped with advanced technology, which allows them to work in the harshest conditions. The excavator you choose must align with the scope of the work and match your site requirements to get the best performance and uptime and reduce downtime or maintenance. This is the reason why proper identification of excavators is necessary when it comes to heavy-duty work.

Mining excavators are heavy machines that are used in mines to do heavy-duty work and can withstand the rigorous conditions of mining. These mining excavators are larger and equipped with reinforced frames, heavy-duty hydraulics, and robust buckets that are used to move large quantities of materials quickly and efficiently and can also withstand the strain of continuous heavy-duty excavation work with extended operating hours. Mining excavators are designed for durability and power, as they have to work in open-pit mines or quarries. They do deep and extensive mining tasks as they are equipped with an advanced hydraulic system, which is used for heavy lifting and digging activities where precision, power, and durability are important.

The load capacity of a mining excavator is a crucial specification to focus on when choosing a mining excavator. The load capacity determines efficiency and productivity. Mining involves lifting heavy materials and moving them from one place to another. The more the load capacity, the more weight the excavator can lift, which is very much essential in large-scale mining operations. The bucket size also acts as the determining factor, as it impacts material handling and loading time.

Operating weight plays a key role in identifying mining excavators. These types of excavators are generally heavier and larger than standard models. The weight provides stability, but the surface needs to be looked at to support the machine at mining sites. The engine power influences the performance of the excavator. These machines are equipped with high horsepower to cater to the needs of heavy-duty mining tasks.

As we know, these mining excavators are built for heavy-duty work, so the machine should be well-built to withstand the harsh conditions and wear and tear at construction sites. Regular maintenance and proper servicing are very important to ensure the durability of the excavator. Timely replacement and repair of faulty parts can increase the longevity of the machine.

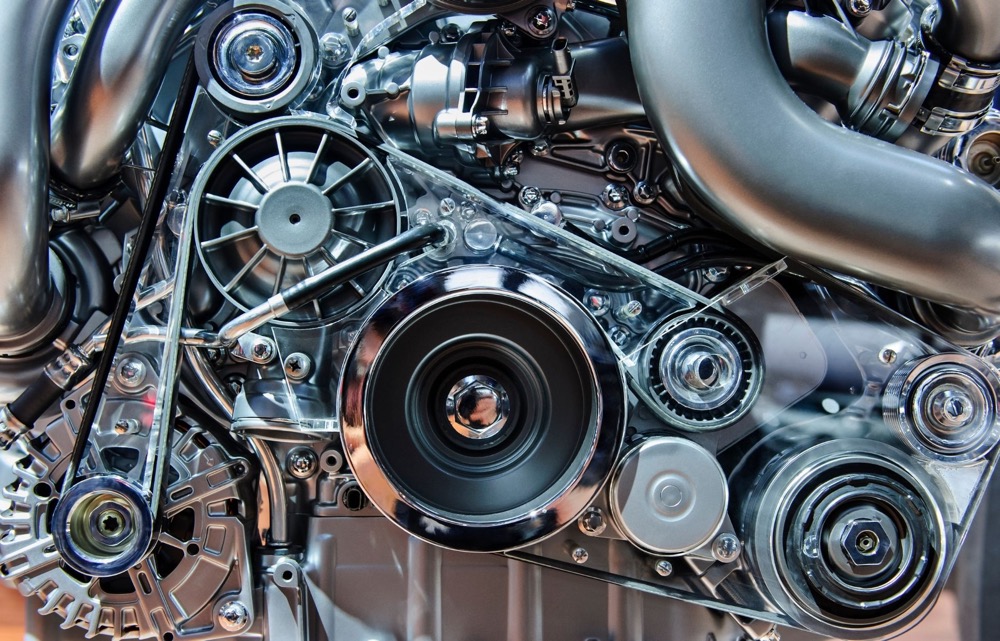

The hydraulic system is the powerhouse of the excavator. With the help of the hydraulic system, the excavator performs its major functions like digging and lifting. Nowadays modern hydraulic systems are equipped with technological advancements that increase efficiency and productivity. It also enables the excavator to carry a heavy load and operate the excavator in rough and challenging terrain. Excavators come with attachments like rock breakers, grapples, buckets, and drilling tools, which are required for different mining activities. So proper selection of attachments according to the requirement is also necessary when choosing the best model for heavy-duty needs.

So, we learned that while choosing the best model for heavy-duty mining activities, we need to consider factors like durability, load capacity, hydraulic power, etc. It is also important to consider the site conditions, the weather conditions, the reputable manufacturer, etc. Combining all the factors and conditions, we need to decide which model will suit the specific job.

A guide to sprockets in construction equipment: types, functions, maintenance, and more

December 3, 2025

Key components of an excavator arm and how to maintain them

December 3, 2025

Final drive maintenance tips: preventing issues before it’s too late

December 2, 2025

Engine cooling system maintenance for heavy equipment 101

December 2, 2025