— November 13, 2025

Gaskets and O-rings are two common types of seals found in heavy equipment. While they both perform the important function of sealing mating surfaces—preventing liquid or gas from escaping—they are quite different in design and function.

O-rings are actually a type of gasket, but they are made from elastomer and are donut-shaped. O-rings fit into a groove between two round mating surfaces and provide a tight seal between components. In heavy equipment, they are commonly used throughout a machine, especially in the hydraulic system.

Gaskets, unlike O-rings, are flat seals that can be made from a variety of materials. While they are typically round, gaskets can come in any shape. Gaskets can be found throughout heavy equipment—and are used in diesel engines and heavy equipment exhaust systems.

While the differences between the two types of seals may seem subtle, they are not interchangeable. Certain components require gaskets, while others require O-rings.

In this guide, we’ll explore the differences and similarities between these important seals, and how they affect heavy equipment performance.

Some common heavy equipment applications for gaskets include:

Some common heavy equipment applications for O-rings include:

Since they are both seals, gaskets and O-rings serve the function of sealing the mating surface between two components.

Both gaskets and O-rings rely on compression to form an air- or liquid-tight seal. As the seal is compressed between the two mating surfaces, the seal expands inside the joint, filling the irregularities between the surfaces.

They are commonly used in heavy equipment to ensure reliable sealing in applications such as hydraulic systems, engine components, pipe connections and more.

Despite having much in common, O-rings and gaskets are still quite different.

Importantly, O-rings feature a higher level of compression than gaskets. Since they are made from elastomer, O-rings are better at expanding between two mating surfaces, providing a seal that is better suited to handling high pressure.

Due to their design, O-rings also require a groove in order to function properly. This sets them apart from gaskets, as gaskets are used for joining two flat surfaces that do not feature a groove.

Compared to O-rings, gasket designs are far more diverse. Since they do not require a groove, gaskets are not restricted to circle-shaped designs. In fact, many gaskets are shaped like squares and rectangles. For example, heavy equipment exhaust gaskets are commonly square or rectangular.

While O-rings are better for high-pressure applications, like in hydraulic cylinders, gaskets are better in high-temperature environments. Since gaskets can be made from a wide variety of materials, including polymers and metals, they are more versatile in their uses.

Since they offer an excellent seal in high-pressure conditions, O-rings are common throughout a machine’s hydraulic system. For example, a machine’s hydraulic cylinders feature a number of dynamic O-ring seals that contain the hydraulic fluid and manage its egress from out of the cylinders.

Other locations you’ll find O-rings on your machine include the machine’s engine and cooling systems, where they play a key role in maintaining liquid seals between components.

O-rings for heavy equipment are commonly made from materials such as nitrile rubber (NBR), fluorocarbon rubber (FKM), silicone rubber (VMQ), or ethylene propylene diene monomer (EPDM).

It’s crucial to select the right material O-ring for your application to ensure proper sealing and longevity. Using an incompatible O-ring can result in premature failure, leaks, reduced performance and potential damage to the equipment.

O-rings are incredibly inexpensive, and commonly cost in the range of $5-10. However, some O-rings in critical systems need to be replaced by a professional, adding to the replacement cost.

In heavy equipment, gaskets are most commonly found in a machine’s engine. For example, a machine’s head gasket, found in the engine, seals the cylinder head to the engine block.

Other types of gaskets include valve cover gaskets, exhaust gaskets and intake gaskets.

Gaskets can be made from different materials, depending on the location of the gasket and its desired function. The choice of material impacts the gasket’s performance and ability to withstand high temperatures and pressure.

In general, gaskets are inexpensive, though some gaskets require professional assistance to be replaced. A typical replacement gasket for heavy equipment engines costs in the range of $10-$100.

Seals, including O-rings and gaskets, are critical to heavy equipment performance. They help keep liquid and gas contained in hoses, tanks, cylinders and other components.

Maintaining your machine’s O-rings and gaskets may be important, but it doesn’t need to be challenging. The MechLink Parts Shop has a wide variety of O-rings and gaskets available for purchase online.

Our selection of O-rings and gaskets includes parts for popular heavy equipment manufacturers such as Takeuchi, Sany and Wacker Neuson. Need help choosing the right O-ring or gasket? Contact one of our parts experts and get personalized assistance.

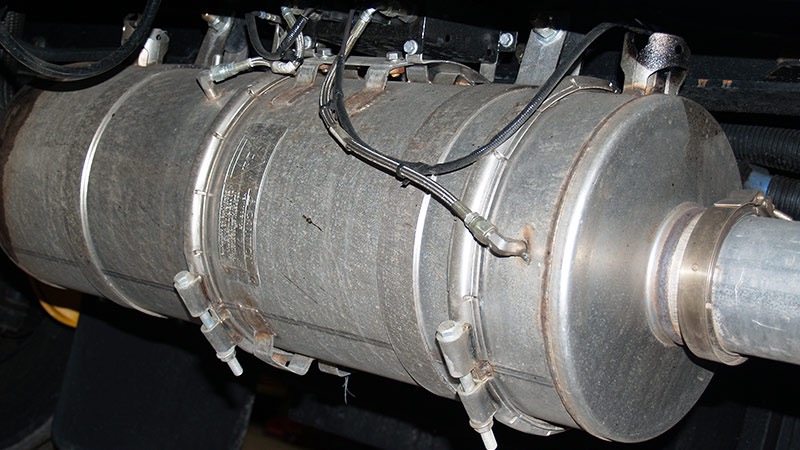

What is a diesel particulate filter and how do you maintain it?

December 26, 2025

Compact track loader attachments: a guide to unlock your machine’s full capabilities

December 26, 2025

Heavy equipment tire wear and what it can reveal about your machine

December 25, 2025

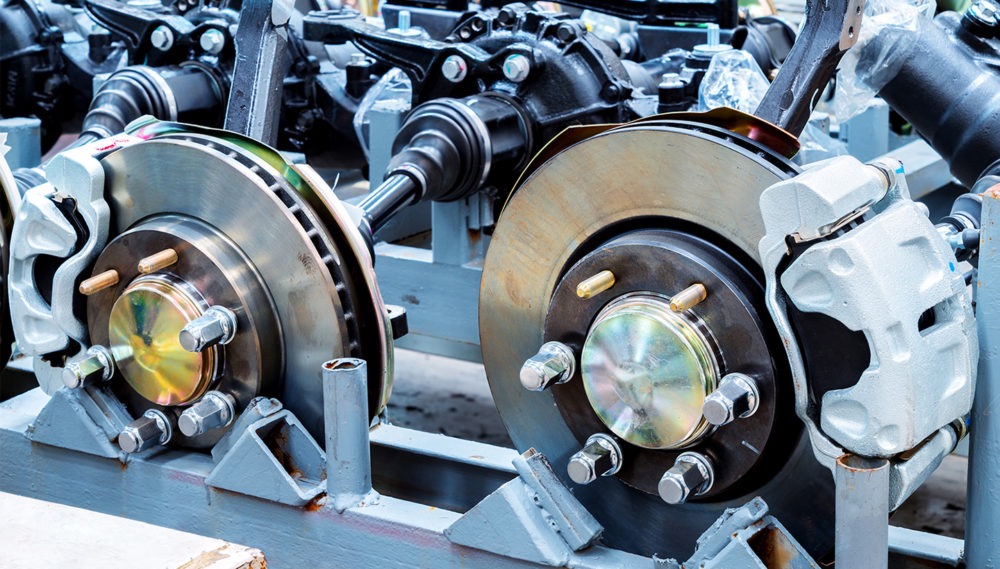

Heavy equipment brake systems: why regular inspections are crucial

December 25, 2025