— Sptember 01, 2025

This blog explains how a hydraulic excavator works, its parts, types, and benefits in industries like construction and mining. It highlights the power, precision, and fuel efficiency of modern excavator machines, including mini excavators, crawler excavators, and long boom excavators from brands like JCB, Tata Hitachi, CAT, SANY, and Volvo, with insights into excavator prices in India.

A hydraulic excavator is a heavy-duty, powerful construction machinery used mostly for digging, lifting, and transporting rock, soil, and debris. Hydraulic systems are used in this type of excavator to execute tasks with high force, precision, and efficiency. The hydraulic system operates through the utilization of high-pressure fluid to drive the motion of different parts to enable the machine to work on tasks that cannot be achieved or would be very difficult by hand.

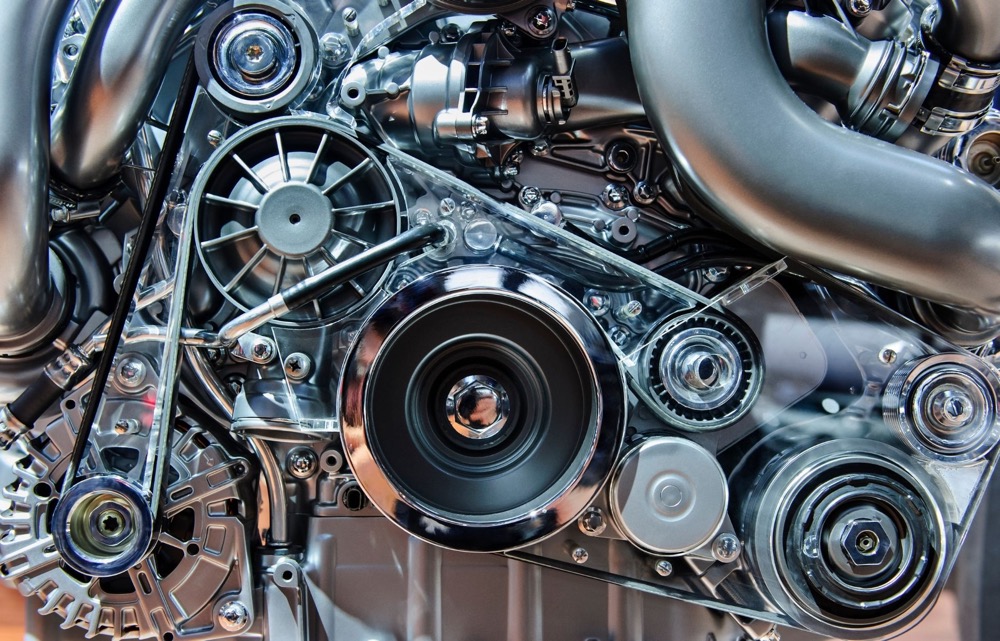

Hydraulic power follows the concept that force can be transmitted using pressurized fluid. This is done by utilizing hydraulic fluid (in most cases oil) to create high pressure in different sections of the machine. As the hydraulic fluid is pumped through the system, it enters hydraulic cylinders, producing force that propels the components of the excavator. The pressurized fluid is able to push or pull heavy weights, allowing the excavator to execute heavy work such as digging, lifting, and grading. The hydraulic efficiency enables the excavators to exert incredible force and accuracy despite their small dimensions and low weights.

The main components involved in this process include:

Hydraulic excavators exist in different forms, each being suited for certain tasks and conditions. Some of the most prevalent types include:

These are the most widely used type of excavators, usually employed for general-purpose digging and building operations. They are available in many sizes and can be applied to a broad array of applications, such as trenching, lifting, and material handling on construction sites.

Smaller than standard excavators, mini excavators are used in tight areas where larger machinery is unable to fit. Used most often for light work such as landscaping, small construction projects, and trenching in close areas, like around utilities or residential neighbourhoods.

Crawler excavators are mounted on tracks rather than wheels and are specifically meant for rugged and uneven grounds. They have great stability and are ideal for deep digging like in mining, quarrying, or demolition activities where heavy lifting and maneuverability on rough grounds are needed.

In contrast to crawler excavators, wheeled excavators are mounted on wheels and thus are faster and easier to move on asphalt roads. They are suitable for city construction, road construction, and other operations where high mobility and effective road travel are a priority.

Long reach excavators are tailor-made for operations involving long digging reach, like dredging or trenching in deep trenches. They are equipped with longer booms and arms and can extend a larger distance or depth compared to regular excavators.

Hydraulic excavators have numerous benefits that make them indispensable for heavy construction, mining, and demolition operations. The following are some main advantages:

Hydraulic systems produce a lot of power, which enables excavators to undertake strenuous tasks such as lifting heavy loads or digging deep trenches easily. The system supplies the energy needed for high-efficiency operations in challenging environments.

The hydraulic system facilitates accurate control of the boom, stick, and bucket, which enables operators to achieve high precision in operations such as grading, trenching, and excavation, which guarantees high-quality results using less effort.

Hydraulic excavators can be fitted with multiple attachments like hammers, augers, and grapples. The ability to do various tasks like demolition, landscaping, and material handling means they are suitable for multiple industries.

New-generation hydraulic excavators are designed to be fuel-efficient, which helps lower cost of operation in the long run and ensures better sustainability in operations.

With increased stability and control, hydraulic excavators reduce the likelihood of accidents, and their working environment is safer for operators and construction personnel.

Designed with strong materials and sophisticated hydraulic components, hydraulic excavators are built to handle heavy loads and aggressive environments and maintain long-lasting performance.

Fast cycle times, easy operation, and lowered downtime allow hydraulic excavators to achieve maximum productivity and accomplish more within a shorter period.

Most modern hydraulic excavators are equipped with lower emission and fuel efficiency capabilities, which make them more eco-friendly when compared to older equipment or less fuel-efficient equipment.

Hydraulic excavators are extremely versatile and are used in a wide range of industries:

In this blog, we’ve explored the importance of hydraulic excavators, their components, working principles, and the key benefits they bring to industries like construction, mining, and demolition. Hydraulic excavators provide powerful performance, precision, and versatility, making them indispensable tools for a wide range of tasks. With advancements in fuel efficiency, safety, and environmental sustainability, they continue to evolve to meet the demands of modern industries.

In the future, advancements in hydraulic technology will bring greater efficiency, lower emissions, and improved safety features to hydraulic excavators. These developments will continue to mark their presence in the future of construction and other heavy industry sectors.

If you’re in the market to buy or lease a hydraulic excavator, MechLink has a full range, along with advice from experts to assist you in selecting the right model for your particular requirements.

A guide to sprockets in construction equipment: types, functions, maintenance, and more

December 3, 2025

Key components of an excavator arm and how to maintain them

December 3, 2025

Final drive maintenance tips: preventing issues before it’s too late

December 2, 2025

Engine cooling system maintenance for heavy equipment 101

December 2, 2025